Main Menu

When it comes to industrial applications, the debate on motor types is crucial. Gear drive motors have become a popular choice among engineers. According to John Smith, a leading expert in motion control, "Gear drive motors offer unmatched reliability and efficiency." This makes them a go-to option for many sectors.

The advantages of gear drive motors are substantial. They provide higher torque outputs and can handle heavy loads with ease. In environments where space is limited, their compact design stands out. However, the installation process can sometimes be tricky. Proper alignment is necessary to avoid premature wear and tear.

Despite their benefits, not every application is a suitable fit. For instance, some may require more rapid acceleration than gear drive motors can provide. This necessitates careful evaluation of project needs. Ultimately, selecting the right motor is a decision that demands reflection and expertise.

Gear drive motors are increasingly favored in industrial environments for several key reasons. One major benefit is their high efficiency. They can convert a significant portion of electrical energy into mechanical power. This efficiency leads to lower energy consumption and reduced operational costs. Another advantage is their ability to produce high torque. This is essential for heavy-duty applications, where consistent force is needed.

When selecting gear drive motors, consider these tips. Assess the specific torque requirements of your application. Overestimating needs can lead to wasted energy. Ensure you understand the gear ratios. Incorrect ratios can lead to suboptimal performance and increased wear. Regular maintenance is crucial. Neglecting this can cause malfunctions, affecting productivity.

Gear drive motors also excel in reliability. They reduce the chance of slipping. This results in smoother operations. However, not all gears can handle extreme conditions. Evaluate your environment—temperature, dirt, and moisture levels matter. Gear lubricants must match these conditions. Ignoring this can lead to premature failure. The right motor can significantly enhance your operations, but selection requires careful thought.

Gear drive motors are known for their high efficiency in industrial applications. Compared to other motor types, they offer several tangible advantages. Their design allows for optimal torque transmission, reducing energy loss. This makes them more economical over time. Users often find that a gear drive motor consumes less power for the same output.

One key metric to consider is speed control. Gear drive motors provide precise control over speed and torque. This adaptability can significantly improve production processes. However, not all applications require such fine control. It’s important to evaluate whether your operational needs align with the capabilities of gear drive motors.

**Tip:** Always assess the specific requirements of your application. This ensures you select the right motor type. Consider how often you need to adjust speed or torque.

Despite their benefits, gear drive motors are not always suitable for every situation. Their complexity can lead to higher initial costs and maintenance requirements. It’s essential to weigh these factors against potential benefits.

**Tip:** Regular maintenance can prevent costly downtimes. Schedule routine checks to keep your motors running efficiently.

| Motor Type | Efficiency (%) | Torque (Nm) | Operational Cost ($/hour) | Lifespan (years) |

|---|---|---|---|---|

| Gear Drive Motor | 90 | 150 | 2.50 | 15 |

| Induction Motor | 85 | 120 | 3.00 | 10 |

| Step Motor | 80 | 40 | 1.75 | 5 |

| Brushless DC Motor | 88 | 70 | 2.20 | 12 |

| Synchronous Motor | 90 | 100 | 2.75 | 8 |

When considering gear drive motors for industrial applications, longevity and maintenance play a crucial role. Gear drive motors typically offer a life expectancy of 10,000 to 20,000 hours. This is significantly higher compared to direct drive motors, which may struggle to reach 5,000 hours under similar conditions. The robust design of gear drives allows them to handle torque fluctuations and heavy loads efficiently.

Maintenance is vital in maximizing the lifespan of these motors. Regular checks on lubricant levels and gear wear can prevent costly breakdowns. A study by the National Institute of Standards and Technology indicates that proactive maintenance strategies can reduce operational costs by up to 30%. Keeping up with scheduled maintenance not only enhances the performance but also ensures safety in the workplace.

Tip: Invest in condition monitoring systems. These tools help detect wear and tear early, allowing for timely interventions. For long-term reliability, consider training staff on proper operational techniques specific to gear drive systems. Understanding the fundamental components can lead to fewer mistakes and better performance. Remember, minor oversights can lead to significant issues down the road.

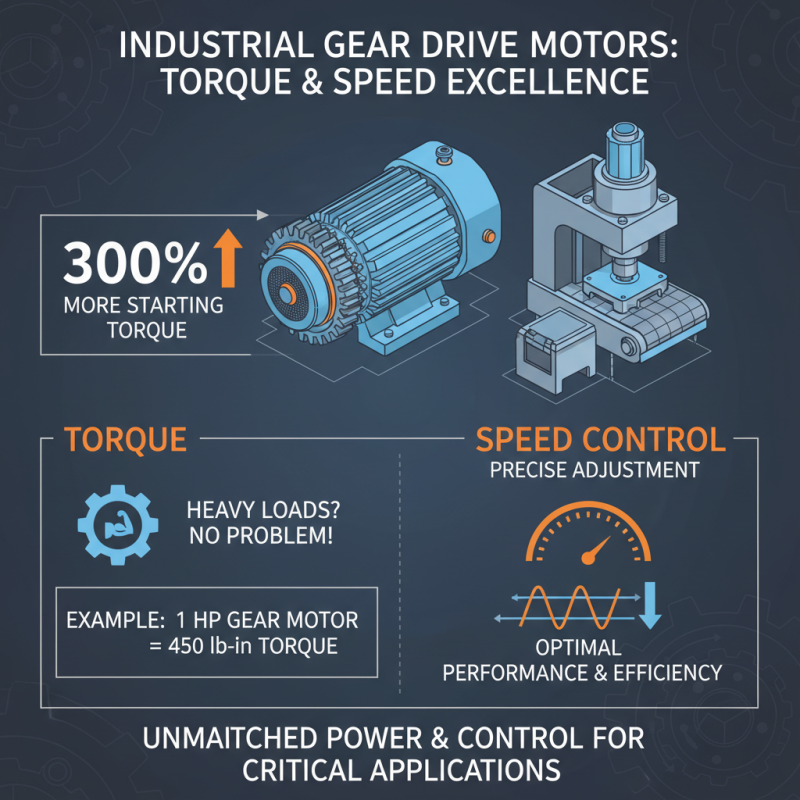

In industrial applications, gear drive motors stand out for their efficiency in torque and speed control. Torque is vital for heavy machinery, with typical gear drives providing up to 300% more starting torque compared to standard motors. This added torque allows operations to begin under heavy loads without straining the system. For example, a gear drive motor rated at 1 HP can deliver an impressive 450 lb-in of torque.

When it comes to speed, gear drive motors provide precise control, an essential feature in many industries. The reduction ratios can reach 100:1 or even higher, allowing motors to operate at lower RPMs while maintaining necessary power. Such control is crucial in applications like conveyors and assembly lines. However, it’s important to consider potential backlash issues at higher reduction levels. Adjustments are sometimes required, reflecting the need for ongoing maintenance.

While gear drives provide significant advantages, they are not always perfect. Some systems may encounter inefficiencies at certain speeds. Understanding the dynamic range of these motors is essential. Reports indicate that a well-calibrated gear drive motor can ensure optimal performance. Still, planners must weigh these factors against application specifics for the best outcome.

In industrial settings, choosing the right motor is crucial. Gear drive motors offer better torque and efficiency. These motors are reliable and provide consistent performance. When examining the return on investment (ROI), gear drive motors often show long-term savings.

Consider energy consumption. Gear drive motors typically consume less energy over time. They also require less maintenance compared to other options. However, initial costs may be higher. This can be a deterrent for smaller operations. Yet, many users report reduced operational costs in the long run.

Another factor to explore is their versatility. Gear drive motors adapt to various applications. This flexibility can lead to better performance across different tasks. Still, some facilities may struggle to optimize their use. Ensuring proper alignment and installation is key. Overcoming such challenges can result in significant benefits.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.