Main Menu

When embarking on any engineering project, understanding the various types of motors is crucial for achieving optimal performance and efficiency. Motors, the driving force behind countless applications—from robotics to home appliances—come in diverse types, each tailored for specific functions and requirements. Whether you are designing a complex mechanism or simply needing a reliable motor for a DIY project, familiarizing yourself with the different categories of motors can profoundly impact the success of your endeavors.

In this article, we will explore the top 10 types of motors you need to know about. From the universally recognized DC motors and AC motors to more specialized types such as stepper and servo motors, each motor type offers unique advantages and drawbacks suited to particular tasks. By gaining insights into their operational principles, strengths, and ideal applications, you can make informed decisions that align with your project's goals. Understanding these motors not only enhances your technical knowledge but also prepares you to tackle a variety of challenges in your engineering projects effectively.

When embarking on a project that involves motorized components, understanding the different types of electric motors available is crucial. Electric motors are the backbone of countless applications, ranging from household appliances to industrial machinery. The most common types of electric motors include AC motors, DC motors, and stepper motors, each serving distinct purposes based on their operational principles.

AC motors, often used in fans, pumps, and compressors, are known for their durability and efficiency in converting electrical energy into mechanical energy. They are typically utilized in applications requiring constant speed and high reliability. On the other hand, DC motors offer variable speed and torque, making them ideal for applications such as electric vehicles and small hobby projects. Their ability to control speed precisely allows for enhanced performance in various consumer electronics. Finally, stepper motors are favored in robotics and automation for their precise positioning capabilities, allowing for accurate movements in systems that demand high precision. Understanding these types of motors is essential for selecting the right one for any project, ensuring optimal performance and efficiency.

This chart provides an overview of common types of electric motors and their applications, illustrating the frequency of use for various projects.

DC motors are essential components for various projects due to their unique characteristics and versatile applications. Unlike AC motors, DC motors provide precise control of speed and torque, making them ideal for tasks that require accurate positioning. Their simplicity in design and ease of control through PWM (Pulse Width Modulation) further enhance their utility in both hobbyist and industrial projects. Whether you're working on robotics, automation systems, or portable devices, understanding the features of DC motors will give you a significant advantage in your design.

**Tips:** When selecting a DC motor for your project, consider factors such as voltage, torque, and speed ratings to ensure optimal performance. It's beneficial to experiment with different motor types and configurations to determine what best suits your needs. Additionally, incorporating feedback mechanisms like encoders can further improve the performance and reliability of your motorized system.

Another critical aspect of using DC motors is their efficient integration with power sources and control systems. Utilizing H-bridge circuits allows for bidirectional control, enabling motors to rotate in either direction. This flexibility is crucial for applications like robotic arms or remote-controlled vehicles. Keep in mind that appropriate heat management strategies should also be applied to prevent overheating during prolonged operation, ensuring the longevity and reliability of your projects.

When exploring AC motors, it's essential to recognize their growing significance in both industrial and home applications. AC motors, which operate on alternating current, are designed to convert electrical energy into mechanical energy efficiently. This makes them ideal for a wide array of uses, from powering large machinery in factories to driving smaller appliances in residential settings. The versatility of AC motors allows them to run continuously with minimal maintenance, a crucial factor in environments where downtime can result in significant losses.

One of the significant advantages of AC motors is their robustness and durability. Designed to withstand harsh operating conditions, they have fewer moving parts compared to their DC counterparts, which translates to a longer lifespan and lower chance of failure. Additionally, AC motors can be easily scaled to meet varying power needs, making them suitable for both high-demand industrial processes and everyday household tasks. This flexibility, combined with their energy efficiency, positions AC motors as a reliable choice for anyone looking to enhance their projects, whether in professional or personal contexts.

Stepper motors play a crucial role in precision control systems, particularly in applications requiring accurate positioning and repeatability. According to a report by MarketsandMarkets, the global stepper motor market is expected to grow from USD 3.6 billion in 2020 to USD 5.2 billion by 2025, demonstrating an increasing adoption in various industries. This surge is largely driven by the need for high precision in robotics, manufacturing, and medical devices, where incremental movement is essential.

One of the distinct advantages of stepper motors is their ability to provide precise control over angular position without the need for feedback systems. This characteristic makes them ideal for applications like CNC machines, 3D printers, and automated assembly systems. A study by Research and Markets indicates that the utilization of stepper motors in 3D printing alone is projected to increase by over 14% annually due to their capability to achieve fine details and minimal error margins. With advancements in technology, modern stepper motors have also become more efficient, offering improved torque and responsiveness, thereby enhancing their effectiveness in high-demand precision control environments.

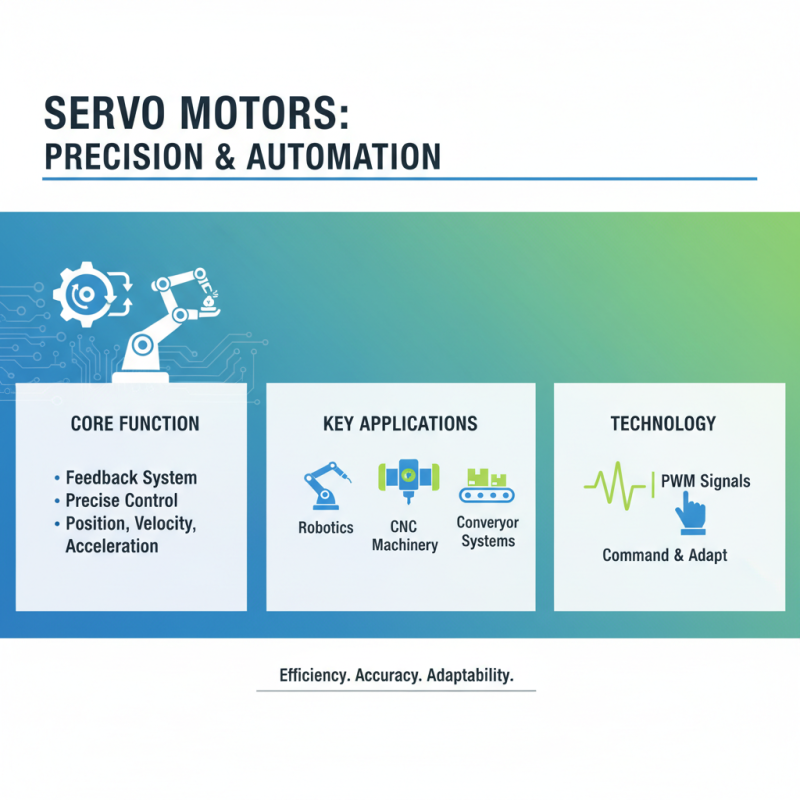

Servo motors are a critical component in many automation solutions, offering precise control and efficiency in various applications. These motors typically incorporate a feedback system, which allows them to adjust their position, velocity, and acceleration with remarkable accuracy. This capability makes servo motors ideal for tasks that demand high precision, such as robotics, CNC machinery, and conveyor systems. By using pulse width modulation (PWM) signals, servo motors are able to receive commands that dictate their movements, enabling them to adapt swiftly to changing operational requirements.

In addition to their precision, servo motors are also valued for their versatility. They can be found in a range of applications across multiple industries, from manufacturing and packaging to medical devices and aerospace. The ability to operate in varying environments and conditions makes them indispensable in automation settings. Furthermore, advancements in servo motor technology continue to push the boundaries of what is possible, enabling smoother motion, enhanced performance, and reduced energy consumption. This ongoing evolution is essential for keeping pace with the increasing demands for efficiency and reliability in modern engineering projects.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.