Main Menu

Choosing the right motors for your needs can be challenging. As John McCarthy, a leading expert in the motors motor industry, once said, “Selecting the correct motor can significantly impact performance.” His insight highlights the importance of making an informed choice.

Proper motor selection involves understanding your requirements. Consider factors like torque, speed, and power supply. Each application demands a specific type of motor. For instance, a simple fan motor differs vastly from a complex robotic motor. It’s crucial to analyze the unique features of each option.

Mistakes in choosing motors can lead to inefficiency. This can result in unnecessary costs and equipment failure. Often, users neglect to research fully. They might overlook essential specifications or assume all motors are the same. This mindset can hinder optimal performance. Understanding your application will lead to better decisions and successful outcomes.

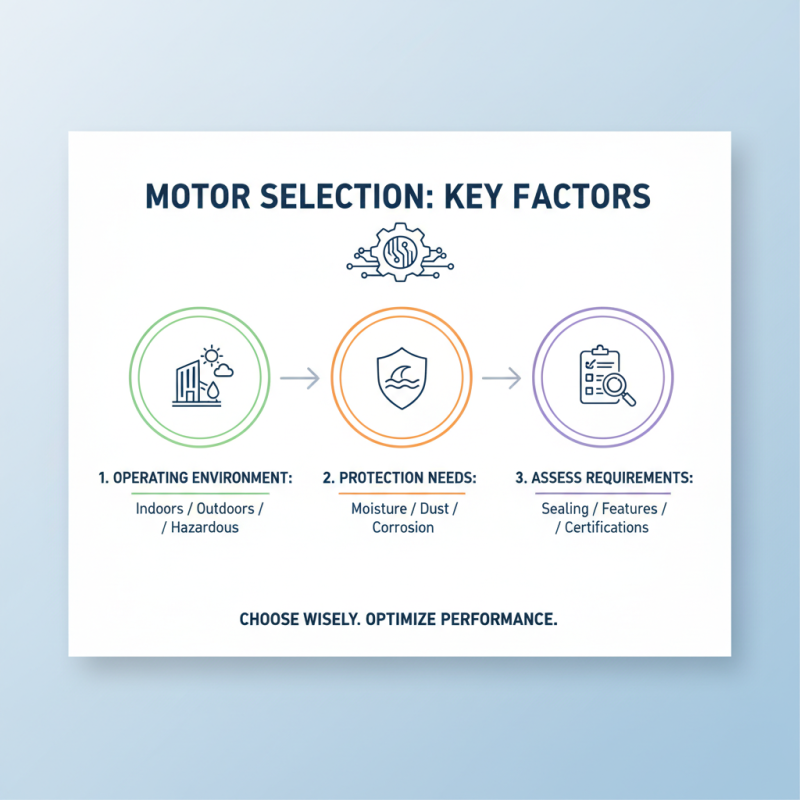

Understanding your specific motor requirements is crucial when selecting the right motor for your application. Consider the environment where the motor will operate. Is it indoors, outdoors, or in a hazardous location? Different settings may require unique features or protection levels. For example, a motor exposed to moisture needs better sealing. Make sure you assess these factors upfront.

Next, think about the power needs of your application. This often involves calculating the required torque and speed. Not all motors can handle the same loads. Some might seem perfect at first glance but fall short under actual conditions. It’s essential to determine your peak and continuous operational requirements. Improper sizing could lead to inefficient performance or premature failure.

Lastly, consider how easy it is to maintain the motor. Some motors are designed for easy access and servicing. Others are not. Think about the lifespan of the motor as well. If frequent replacements are not feasible, invest time in choosing a more durable option. Finding the right balance between cost, performance, and maintenance can be challenging but is well worth the effort.

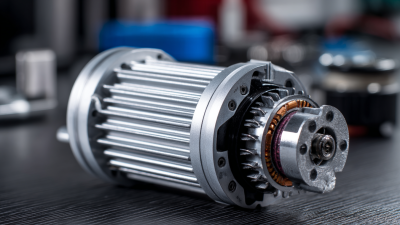

Choosing the right motor requires a clear understanding of motor types and their applications. Electric motors dominate various industries, making up about 70% of the total energy consumed in the industrial sector. DC motors are popular for their straightforward speed control and ease of use. AC motors, especially induction motors, are widely used in fans, pumps, and conveyors due to their durability and low maintenance.

However, not all applications benefit from the same motor type. For instance, servo motors provide high precision, which is crucial in robotics and CNC machinery. According to a report from the International Electrotechnical Commission, the need for energy-efficient motors continues to rise, showing a growth rate of 6% annually. Motors must be selected not only on power and size but also on efficiency ratings.

It's important to consider the environment and application before choosing a motor. Often, manufacturers overlook the compatibility of motor specifications with their operational context. Factors such as load type and duty cycle need careful evaluation. Errors in this stage can lead to inefficiencies and unhappy end-users. There’s a fine line between optimal performance and energy waste. Finding the right balance is essential for sustainable operations.

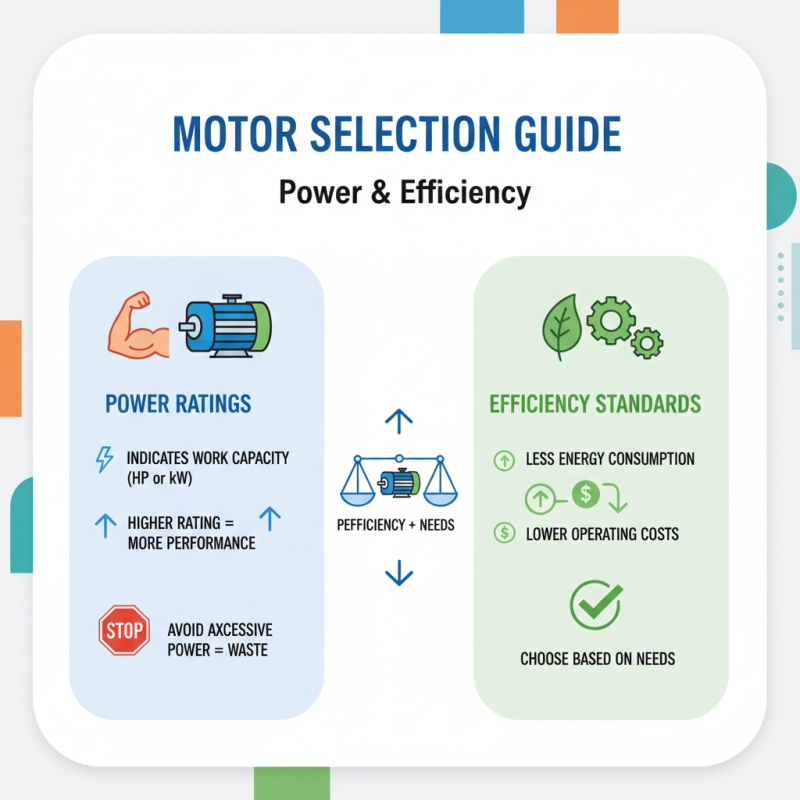

Choosing the right motor involves understanding power ratings and efficiency standards. Power ratings indicate how much work a motor can perform. Typically, these ratings are given in horsepower or kilowatts. A higher power rating usually means greater performance, but it also leads to increased energy consumption. Fine-tune your choice based on actual needs. A motor with excessive power may waste resources.

Efficiency standards are equally critical. They determine how much of the electrical energy is converted into mechanical energy. Motors with high efficiency ratings waste less energy as heat. Look for motors that comply with recognized efficiency benchmarks. While higher efficiency often leads to higher upfront costs, the long-term savings on electricity can be significant. Consider how often the motor will run. If used continuously, an efficient motor is a worthwhile investment.

A common mistake is to overlook these details. Many choose solely based on price or availability. This can lead to poor performance or increased costs. Reflect on the specific application requirements before making a purchase. A motor that seems ideal may not actually meet operational demands. Evaluating power ratings and efficiency can seem complex. Yet, it is essential for making an informed choice.

Selecting the right motor involves careful consideration of size and weight. A motor that's too large might not fit in your designated space. Conversely, a motor that's too small may fail to provide the needed power. Consider the overall dimensions of your project. Measure the area where the motor will be installed. Ensure there's enough room for ventilation and any necessary wiring.

Weight is another crucial factor. A lightweight motor simplifies installation, especially in portable applications. However, heavier motors can be more robust. Ask yourself: Does the motor's weight affect mobility? Evaluate how the weight impacts your project. Sometimes, a compromise between size and power is necessary.

Installation factors can greatly influence your choice. Think about accessibility for maintenance. A motor located in a hard-to-reach area can pose problems down the line. Plan the installation carefully. Analyze how the motor interacts with other components. Misalignment can lead to failures or inefficiencies. Reflect on these aspects to enhance your project’s success.

When choosing motors, budget plays a vital role. You need to determine your initial costs. However, it’s also important to look at long-term maintenance costs. Sometimes, a cheaper motor might cause unexpected issues later. These hidden expenses can add up quickly and affect your overall investment.

For example, higher quality motors might have a higher upfront cost. But they tend to require less frequent repairs or replacements. This could save you money in the long run. Think about power consumption too. A motor that uses more energy will increase your utility bills. Conduct thorough research on energy efficiency ratings. In the end, what seems like a good deal may not be the best choice.

Reflecting on your specific needs is crucial. Consider factors like workload and environment. Sometimes, selecting a motor that fits your application perfectly might have a higher initial price. However, it can significantly reduce downtime and maintenance needs. Balancing initial costs with potential expenses is an art. Strive to make an informed decision that supports both immediate and future requirements.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.