Main Menu

In the realm of robotics, the choice of the right components can significantly determine the performance and efficiency of a project. Among the myriad of components, DC motors for robots play a pivotal role in providing the necessary motion and control for robotic systems. Whether you are a seasoned engineer or a novice hobbyist, understanding the nuances of selecting DC motors can enhance your robotic creations, making them more responsive and capable.

When embarking on your robot-building journey, it becomes essential to consider several key factors that influence the selection of DC motors. These factors range from torque requirements and speed to efficiency and power consumption. A well-informed choice can mean the difference between a smoothly functioning robot and one that struggles to achieve its designed tasks. By exploring the critical aspects of choosing DC motors, you will gain insights that build a solid foundation for your robotic projects, ensuring optimal performance tailored to your unique needs.

This guide will walk you through the top ten tips for selecting the perfect DC motors for your robots, equipping you with the knowledge to make informed decisions. Each tip is designed to simplify the selection process, allowing you to focus on innovation and creativity in your robotic designs while ensuring reliability and effectiveness in operation.

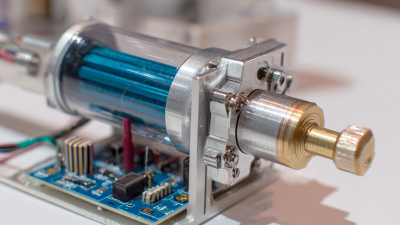

When embarking on robot projects, understanding the fundamentals of DC motors is essential. DC motors are widely used in robotics due to their simplicity, efficiency, and ease of control. They convert electrical energy into mechanical energy through the interaction of magnetic fields, allowing for precise movement and speed control. The basic components include a rotor, stator, commutator, and brushes, all of which work together to enable rotation. Familiarity with these components will help you make informed choices when selecting a motor for your project.

Furthermore, it is crucial to grasp the key specifications of DC motors that influence their performance in robotic applications. Consider factors such as torque, speed, and voltage ratings, as they directly impact how well a motor will suit specific tasks. The torque determines the motor's ability to move heavy loads, while the speed rating affects how quickly the robot can operate. Additionally, understanding the power requirements can aid in ensuring the motor is compatible with your robot’s power supply. By solidifying your knowledge of these basics, you can effectively select the right DC motors that will enhance your robotics projects and achieve desired operational goals.

| Tip | Description | Considerations | Examples of Applications |

|---|---|---|---|

| 1. Determine the Required Torque | Identify the torque needed to move your robot based on weight and load. | Calculate before selecting a motor to avoid underperformance. | Robotic arms, mobile robots. |

| 2. Evaluate Speed Requirements | Consider how fast the motors need to operate for effective performance. | Balance speed with torque for optimal results. | Drones, line-following robots. |

| 3. Select the Right Voltage | Choose a voltage compatible with your power supply and components. | Standard voltages are typically 6V, 12V, or 24V. | Electric carts, automated guided vehicles. |

| 4. Consider Motor Type | Different motor types (brushed vs brushless) have distinct characteristics. | Brushed motors are simpler; brushless motors have higher efficiency. | RC vehicles, robotic vacuum cleaners. |

| 5. Assess Efficiency Ratings | Look for motors with high efficiency to extend battery life. | Efficiency can affect overall robot performance. | Solar-powered robots, endurance robots. |

| 6. Review Size and Weight | Make sure the motor fits within the design constraints of your robot. | Larger motors provide more power but increase weight. | Compact robots, miniature applications. |

| 7. Check for Compatibility | Ensure the motor works with your existing electronics and control systems. | Evaluate sensor and controller compatibility. | Fully automated systems, machine learning-based robots. |

| 8. Research Motor lifespan | Look for motors with good durability and lifespan based on usage conditions. | Consider operational environments. | Industrial robots, outdoor robots. |

| 9. Analyze Cost vs Performance | Balance cost with the performance you need for your project. | Invest in quality where it matters most. | Cost-sensitive projects, high-performance applications. |

| 10. Plan for Future Upgrades | Choose motors that allow for easy upgrading or replacement. | Consider modularity in design. | Prototype projects, educational robotics. |

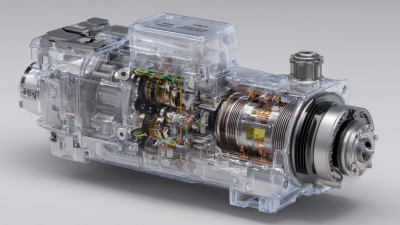

When selecting DC motors for robot projects, several key specifications are critical to ensure optimal performance. First, consider the motor's voltage rating, as it will determine the compatibility with your power supply. A motor's voltage directly impacts its RPM (revolutions per minute) and torque capabilities. It's essential to choose a motor rated for a voltage that matches or is slightly below that of your power source to avoid overheating or damaging the motor.

Another important specification is torque, which is the rotational force the motor can exert. Assess the requirements of your robot, including the weight it needs to carry and the type of movement it will perform. For instance, higher torque is necessary for applications involving lifting or pushing heavy loads. Additionally, looking at the motor's RPM provides insight into the speed of the robot’s movements, allowing you to balance speed and power based on your project’s objectives. Understanding these specifications will help you select the right DC motor to meet your project's demands effectively.

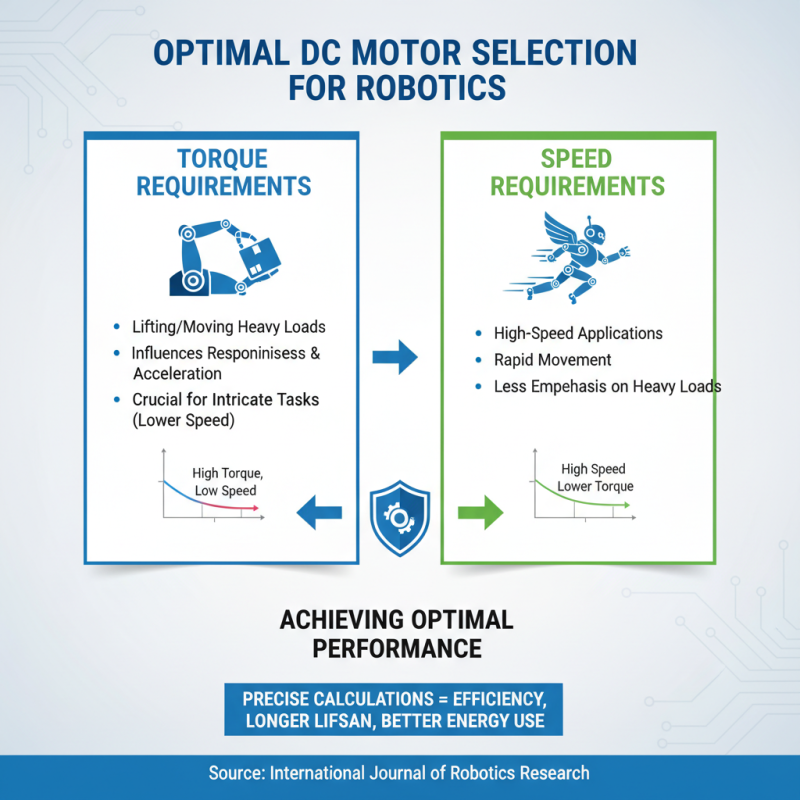

When selecting DC motors for robotic projects, evaluating torque and speed requirements is crucial to achieving optimal performance. The torque required for a robot not only determines its ability to lift or move heavy loads but also influences its responsiveness and acceleration. According to a report by the International Journal of Robotics Research, precise torque calculations can prevent inefficiencies and ensure that motors operate within the optimal range of performance, thus extending their lifespan and improving energy consumption. For instance, a robot designed for intricate tasks may need a motor delivering a higher torque at lower speeds, while a robot intended for high-speed applications might prioritize speed over torque.

Furthermore, the relationship between speed and torque in DC motors can be understood through the motor's torque-speed curve, which depicts the trade-off between these two parameters. Research from the IEEE Robotics and Automation Society indicates that understanding this curve allows engineers to select motors that maintain a balance suited to the robot's specific tasks. For example, during acceleration, where higher torque is necessary, a motor may require gearing to maximize speed without compromising torque. Therefore, analyzing the intended movement patterns and load requirements thoroughly can guide the choice of motor specifications, ensuring that the robot can operate efficiently under varying conditions.

When it comes to robotic applications, the efficiency of DC motors plays a crucial role in determining the overall performance and sustainability of the project. According to a recent report by the International Federation of Robotics, energy efficiency in motors can contribute significantly to reducing operational costs.

In robotic systems, the adoption of efficient motors can lead to performance enhancements, including improved speed control and reduced heat generation, which is critical for extending the lifespan of electronic components and enhancing safety.

Moreover, selecting motors that operate at high efficiency rates can result in up to a 30% reduction in energy consumption compared to traditional options. This is particularly relevant in applications such as autonomous drones and mobile robots, where battery life is a crucial factor in design considerations.

The U.S. Department of Energy has indicated that integrating high-efficiency electric motors can lead to significant savings; for example, the use of advanced DC motors could potentially save over $1 billion in energy costs annually across industry sectors. As such, prioritizing motor efficiency during the design phase not only optimizes the robot's performance but also contributes to more sustainable practices in robotics.

When selecting DC motors for your robot projects, it's crucial to avoid several common pitfalls that can hinder your design's performance and efficiency. One frequent mistake is underestimating the required torque. Many builders focus solely on speed without considering the actual load the motor needs to handle. To avoid this, assess the mechanical requirements of your project thoroughly, calculating the torque needed to move your components smoothly. This will help in selecting a motor that can perform optimally under real-world conditions.

Another common error is neglecting the voltage and current limits of the motor. Choosing a motor without a clear understanding of the power source and system requirements can lead to overheating or even motor failure. It's essential to match the motor's specifications with your power supply to ensure reliability and longevity. Additionally, consider the operating environment; motors that will be subjected to harsh conditions may need specific features like sealed designs to prevent damage. By avoiding these pitfalls and being thorough in your evaluations, you can ensure that your chosen DC motors will effectively power your robot project.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.