Main Menu

In the rapidly evolving field of robotics, the adoption of precision DC motors has emerged as a crucial factor for enhancing performance and reliability. According to a report by MarketsandMarkets, the global DC motor market is projected to reach $42.1 billion by 2025, driven by the increasing demand for automation in various industries.

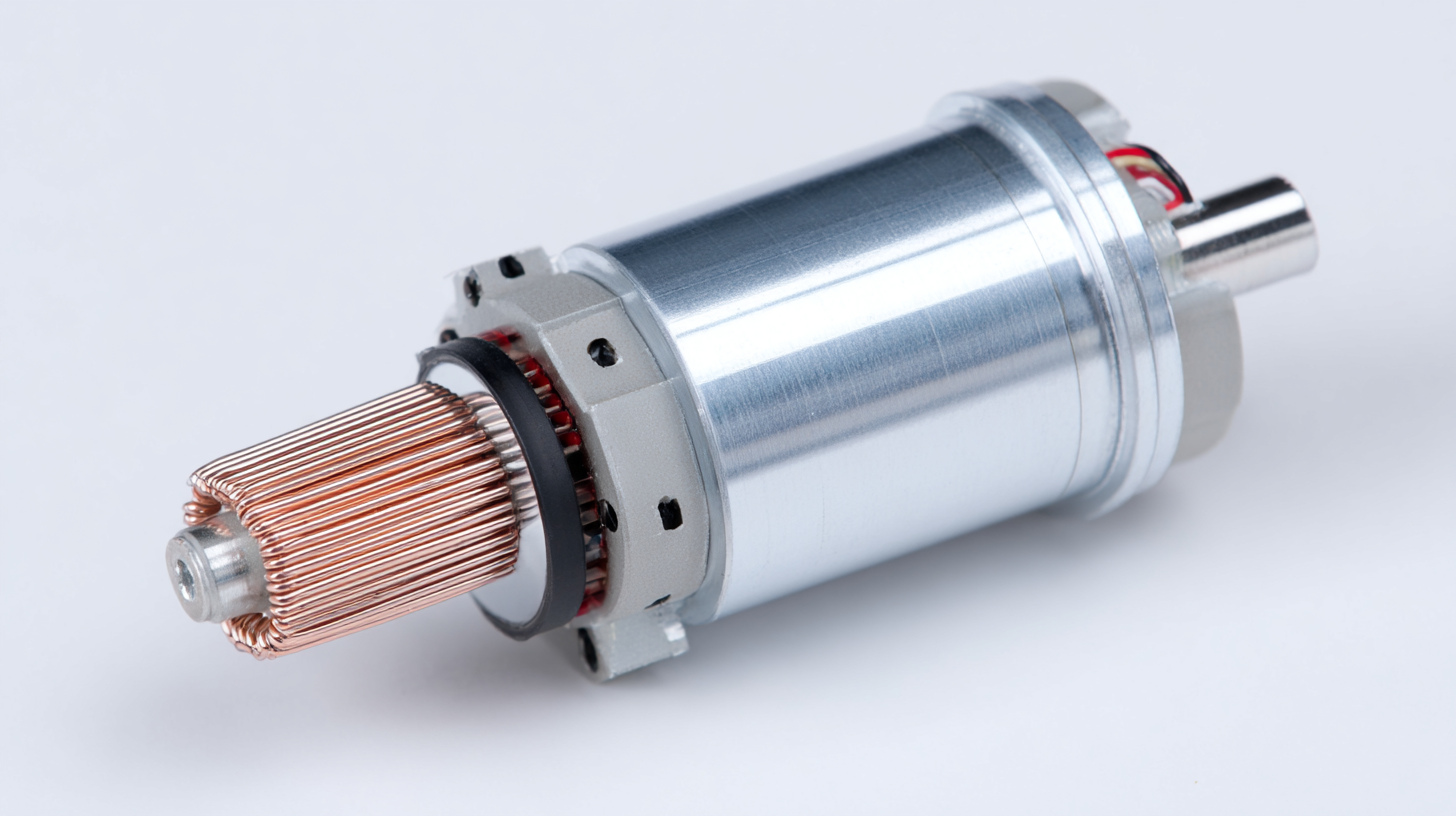

Precision DC motors stand out due to their superior accuracy, efficiency, and control capabilities, making them indispensable in applications ranging from industrial automation to consumer robotics. These motors enable precise motion control and improve the overall functionality of robotic systems, leading to more sophisticated and versatile designs.

This blog will explore how best precision DC motors can significantly enhance robotics applications, followed by a comprehensive installation guide to ensure optimal performance.

Precision DC motors play a crucial role in modern robotics applications, providing the necessary accuracy and control required for sophisticated robotic movements. These motors offer superior speed regulation and torque performance, enabling robots to execute complex tasks with precision. This is especially important in environments where fine motor skills are essential, such as in medical robotics or intricate assembly lines. By maintaining a consistent performance across different load conditions, precision DC motors enhance the reliability and efficiency of robotic systems.

In addition to their performance characteristics, the design and installation of precision DC motors are vital for optimizing robotic applications. Engineers must consider factors such as motor size, weight, and compatibility with the overall robotic architecture during the installation process. Proper integration ensures that the motors operate harmoniously within the system, minimizing the risk of mechanical failures and maximizing responsiveness. Thus, understanding the specific requirements and characteristics of precision DC motors is essential for developers aiming to push the boundaries of robotics technology.

Precision DC motors have emerged as a cornerstone in the development of advanced robotics applications, driven by their unique key features. One of the primary attributes is their exceptional torque-to-weight ratio, which significantly enhances the responsiveness and agility of robotic systems. According to a report by the International Federation of Robotics, the demand for precision motors in automation and robotic systems is projected to grow at a CAGR of 7.9% through 2025, highlighting their critical role in modern engineering.

Another vital feature of precision DC motors is their superior control capabilities. These motors are designed to deliver consistent performance across a wide range of speeds and loads. A study by the IEEE indicates that the implementation of precision DC motors can improve the accuracy of robotic movements by up to 30%, which is crucial for tasks requiring meticulous operational precision, such as assembly and surgery. Furthermore, the integration of advanced feedback systems in these motors allows for real-time adjustments, providing an unparalleled level of performance that is essential in robotics applications. With these advantages, precision DC motors are not only enhancing current technologies but also paving the way for innovative solutions in the robotics field.

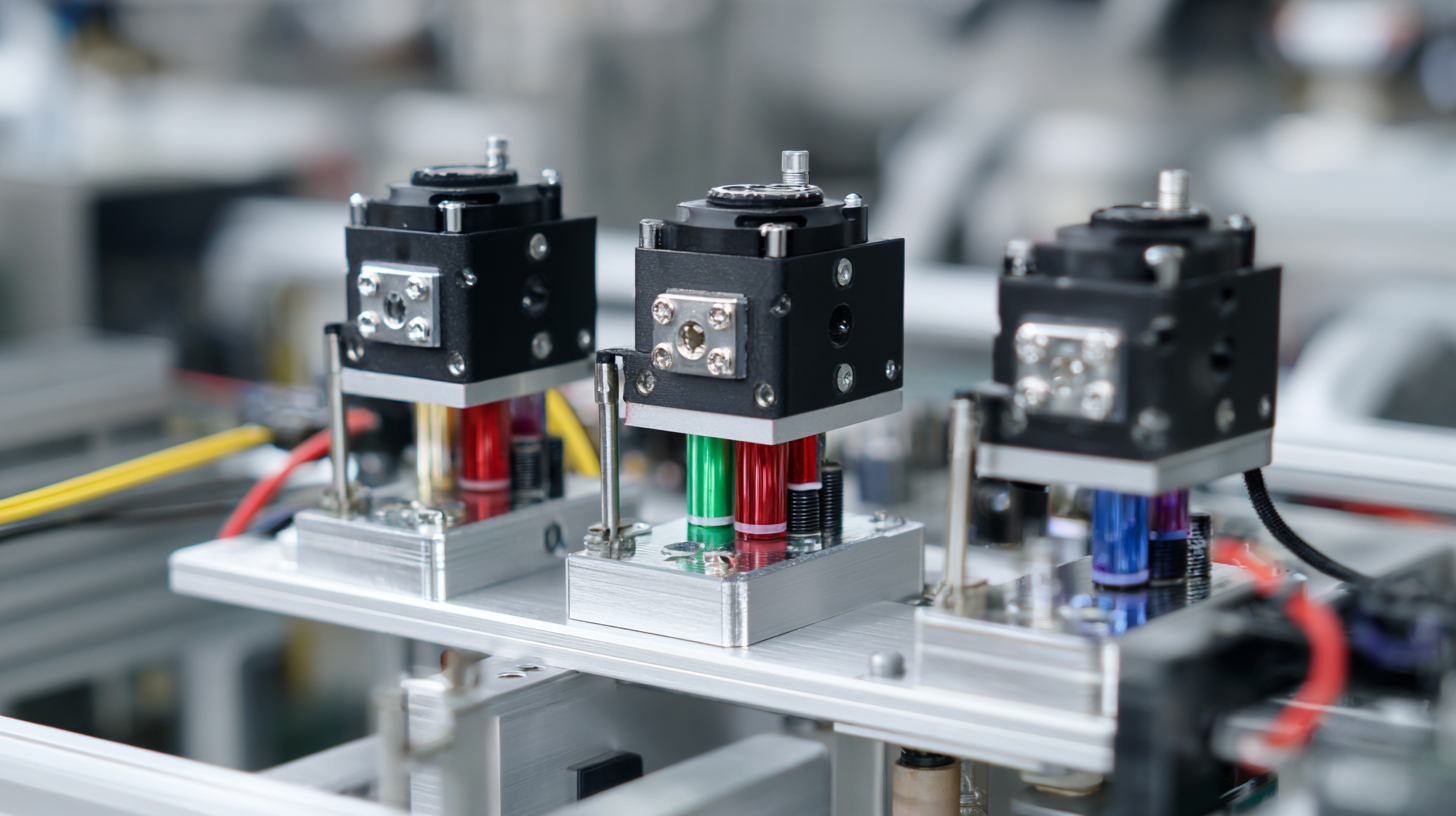

When it comes to incorporating precision DC motors into robotics, a clear and effective installation guide is essential for optimal performance. Begin by gathering all necessary tools, including suitable screws, soldering equipment, and a multimeter. A clean workspace will enhance your efficiency during the installation process. Before connecting the motors, ensure that your robotics platform is compatible with the motor specifications, such as voltage and torque ratings.

Tip: Always double-check wiring connections and polarity before powering up the motors. Misconnections can lead to damage or malfunction, hindering your project's success. Additionally, implementing a heat management strategy will extend the life of your motors, especially under heavy loads.

Next, secure the motors to the frame of your robot, utilizing mounting brackets if necessary. This will provide stability and reduce vibrations during operation. Programming the motor controls should follow installation; make sure to test each motor individually to confirm they respond accurately to commands.

Tip: Utilize debugging tools to streamline the programming process, which can help identify any issues early on, minimizing troubleshooting later. By following this systematic approach, you can ensure that your robotics project runs smoothly and effectively.

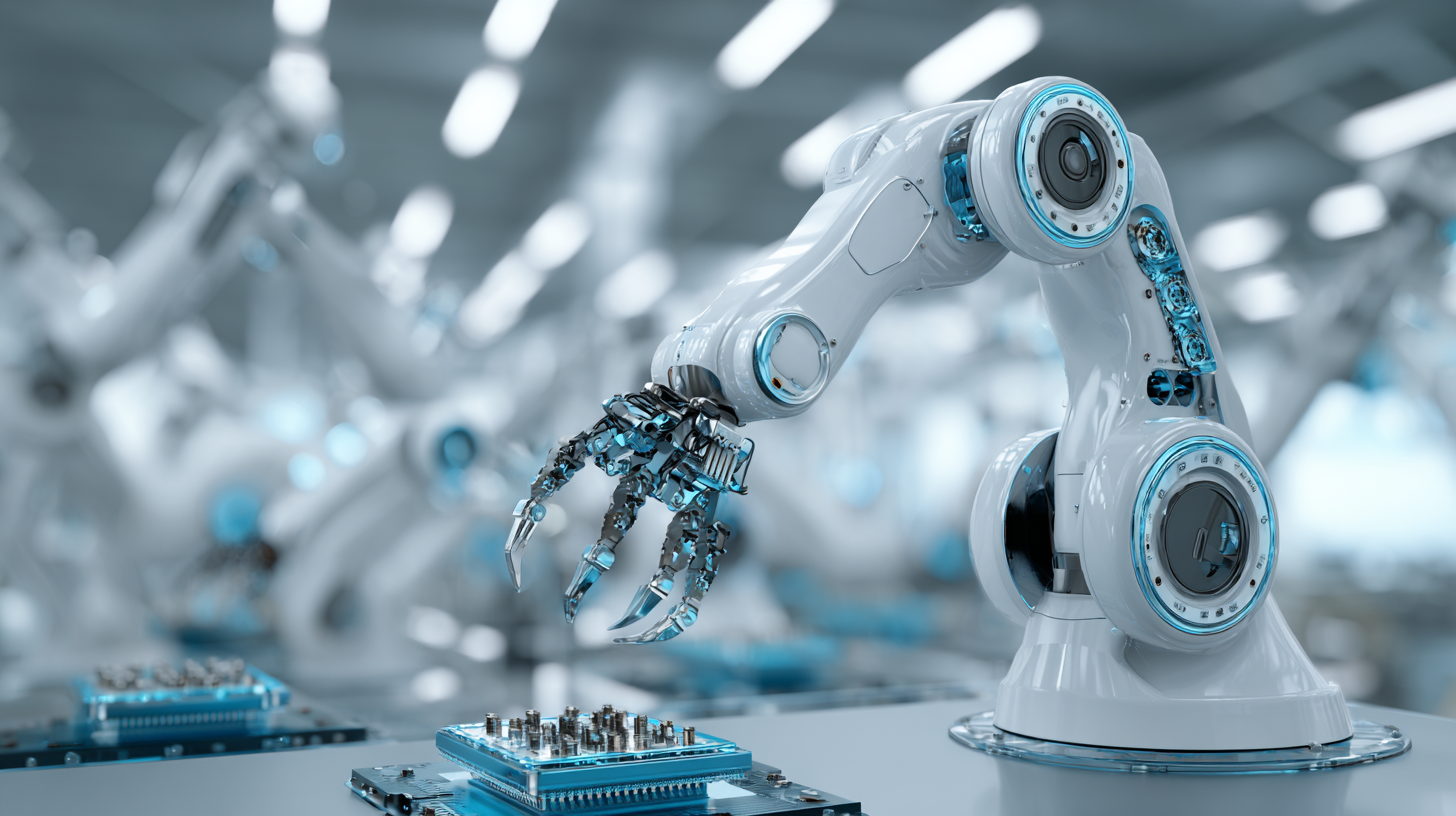

Integrating precision DC motors into robotics applications can significantly enhance performance, efficiency, and precision. According to a report by Allied Market Research, the global robotics market is expected to reach $210 billion by 2025, with precision motors playing a crucial role in this growth. These motors provide high torque at low speeds, making them ideal for tasks requiring precise manipulation and control, such as in robotic arms and autonomous vehicles.

When working with precision DC motors in robotics, operators may encounter various issues that can hinder performance. One common problem is the motor stalling, which can occur when the load exceeds the motor's torque limit. This often manifests as a sudden pause or unresponsiveness in the robot's movements. To troubleshoot, first ensure that the motor is appropriately sized for the application and check the weight distribution of the load. Adjusting the gear ratio or reducing the load can often resolve the stalling issue.

Another frequent challenge is electrical noise, which can lead to erratic motor behavior or communication issues within the robotic system. This noise can stem from poor wiring or insufficient power supply filtering. To mitigate these issues, inspect all electrical connections for tightness and integrity. Implementing decoupling capacitors on the power lines can help smooth out power variations. Additionally, shielding sensitive components from electromagnetic interference will ensure smoother operation and more reliable communication between the motor and its controllers.

| Application Area | Motor Type | Voltage (V) | Torque (Nm) | Speed (RPM) | Common Issues |

|---|---|---|---|---|---|

| Mobile Robots | Brushed DC Motor | 24 | 0.5 | 200 | Overheating, Speed Fluctuation |

| Industrial Automation | Brushless DC Motor | 48 | 1.2 | 3000 | Electrical Noise, Excessive Vibration |

| Robotic Arms | Coreless DC Motor | 12 | 0.25 | 150 | Loss of Position, Stalling |

| Drones | High-speed DC Motor | 11.1 | 0.75 | 25000 | Short Battery Life, Inconsistent Thrust |

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.