Main Menu

In an era marked by rapid technological advancements and increasing energy efficiency demands, the quest for sourcing the best industrial motors has become more critical than ever in 2023. According to a recent report by MarketsandMarkets, the global industrial motor market is projected to reach $192.0 billion by 2025, growing at a CAGR of 6.2%. This growth is fueled by the rising need for automation and improved operational efficiencies across various industries. Innovative approaches to sourcing these motors not only help companies stay competitive but also enhance their sustainability efforts in line with modern standards. As businesses look to maximize performance while minimizing environmental impact, understanding the latest trends and technologies in industrial motors is essential for making informed procurement decisions.

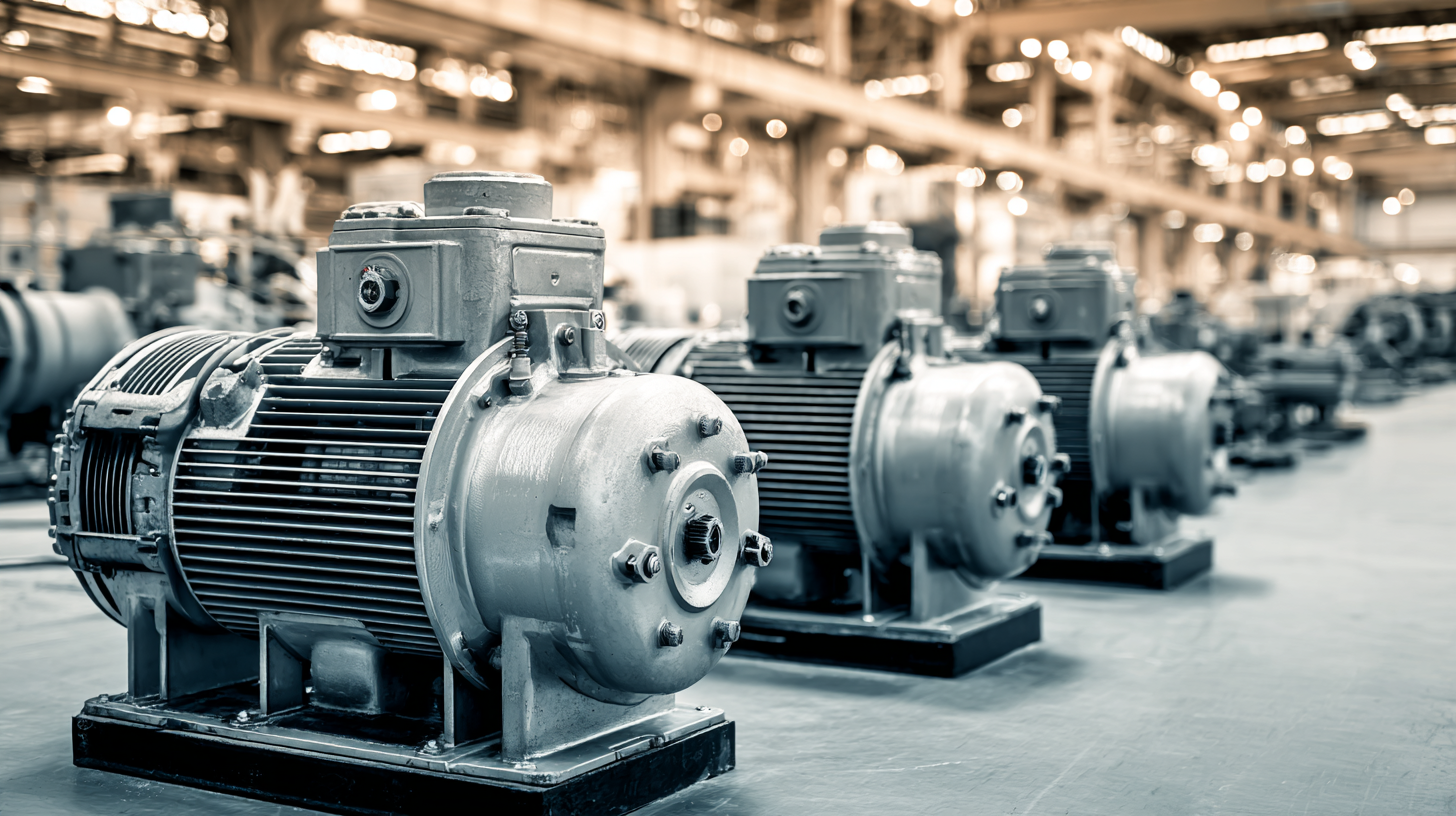

When sourcing industrial motors in 2023, it is crucial to establish a robust set of criteria that ensure the selected motors meet both performance and efficiency standards. First and foremost, understanding the specific application requirements is vital. This includes assessing the environment in which the motor will operate, such as temperature extremes, humidity levels, and exposure to dust or corrosive substances. Different motors are designed for unique conditions, so matching the motor's specifications to its intended use can drastically affect longevity and performance.

Another key criterion is energy efficiency. With rising energy costs and a growing emphasis on sustainability, selecting motors that comply with the latest energy regulations is critical. Evaluating the efficiency ratings, such as the Energy Efficiency Index (EEI), can help identify motors that minimize electricity consumption while maintaining optimal performance. Additionally, examining the motor's maintenance requirements and overall durability will ensure a lower total cost of ownership in the long run. Overall, a comprehensive evaluation based on these criteria can guide manufacturers to the best industrial motor solutions tailored to their specific needs.

| Motor Type | Power Rating (kW) | Efficiency (%) | Speed (RPM) | Torque (Nm) | Application |

|---|---|---|---|---|---|

| AC Induction Motor | 15 | 92 | 1500 | 90 | Pumps |

| DC Brushless Motor | 10 | 95 | 3000 | 35 | Robotics |

| Stepper Motor | 2 | 85 | 600 | 1.2 | CNC Machining |

| Servo Motor | 5 | 90 | 3600 | 20 | Conveyor Systems |

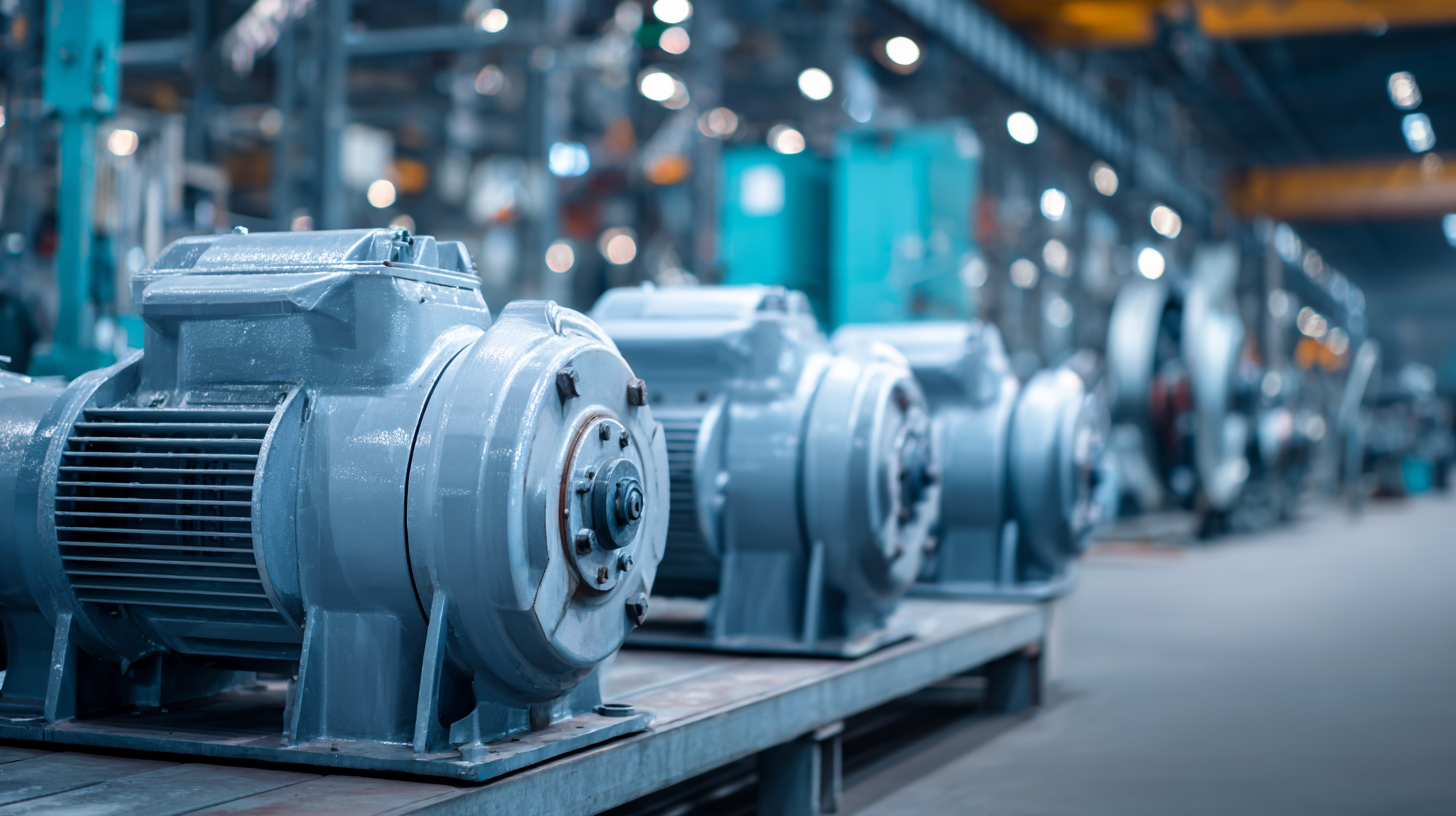

The industrial motor market is poised for significant growth, with the low voltage electric motor segment expected to reach approximately $38.5 billion by 2035 at a CAGR of around 3.05% during the 2025-2035 period. As various industries increasingly seek efficiency and sustainability, the demand for low voltage electric motors continues to surge. These motors are especially vital in applications that require precise control and energy efficiency, making them an essential choice for both industrial and commercial settings.

Furthermore, the UK electric motor market is projected to expand from $6 billion in 2024 to an estimated $12.9 billion by 2035, reflecting robust growth driven by innovations and advancements in technology. Similarly, the German electric motors market is expected to almost double from $9 billion in 2024 to $19 billion by 2035. These trends highlight the growing reliance on electric motors as industries prioritize cleaner energy solutions and enhanced operational efficiencies. Understanding the distinct types of electric motors—such as induction motors, brushless motors, and synchronous reluctance motors—not only assists in sourcing the best products but also enhances application-specific solutions tailored to the needs of various sectors.

In 2023, the sourcing of industrial motors has evolved significantly, necessitating innovative approaches for efficient procurement. One emerging technique is the adoption of data-driven supply chain management strategies. According to a recent report by IHS Markit, companies utilizing advanced analytics in their procurement processes can reduce motor sourcing time by up to 30%. This shift not only streamlines operations but also enhances decision-making, allowing businesses to select the best motors that align with their performance requirements and budget constraints.

Furthermore, leveraging digital marketplaces has revolutionized how industries procure motors. A study by Research and Markets indicates that the online marketplace for industrial components is expected to grow at a CAGR of 7.4% from 2023 to 2030. These platforms facilitate access to a broader range of suppliers, enabling companies to compare prices, quality, and delivery times more effectively. By embracing these innovative sourcing techniques, businesses can ensure they remain competitive while meeting the increasing demand for high-quality industrial motors.

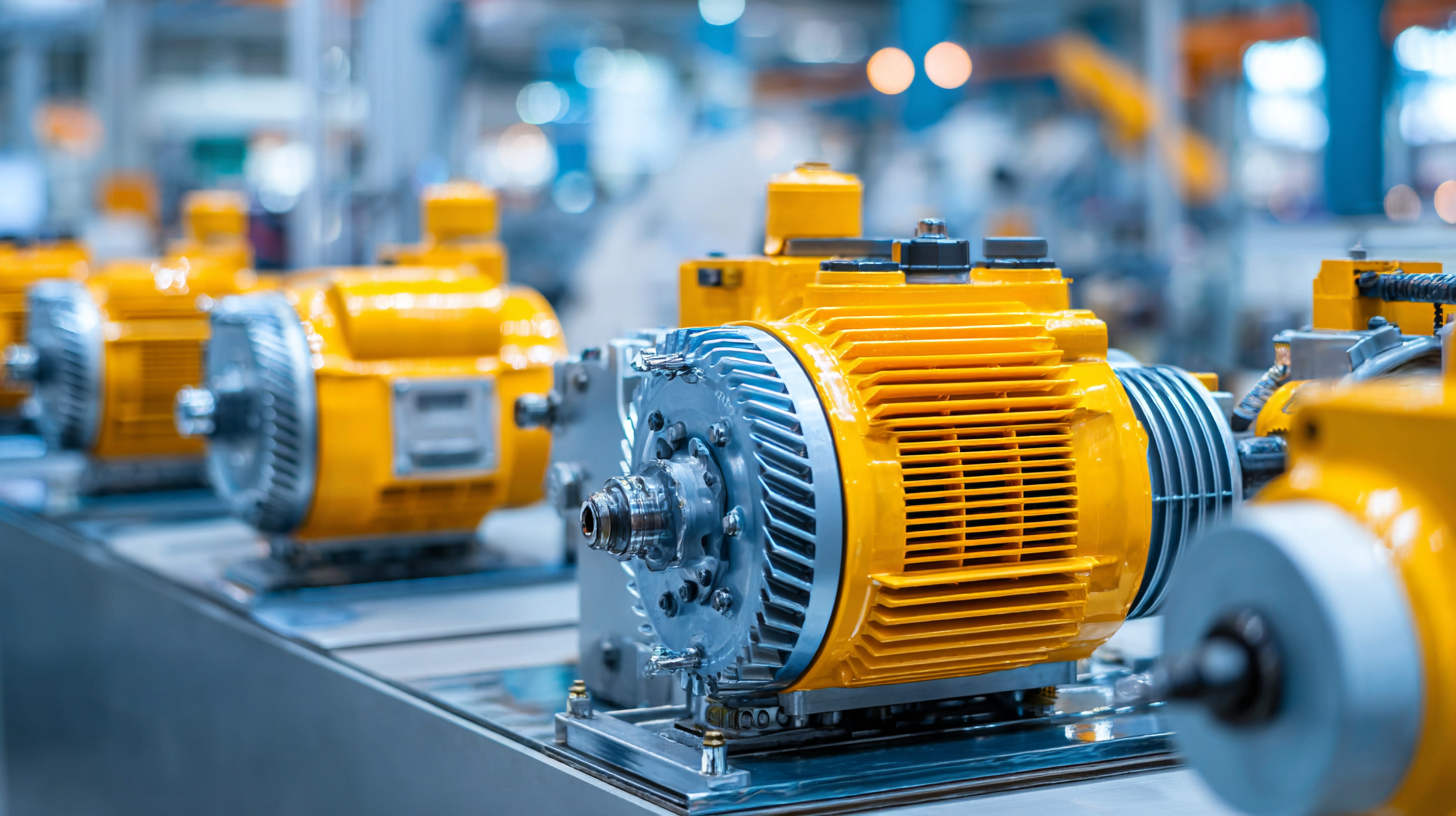

In 2023, the landscape of industrial motor technology is witnessing remarkable transformations driven by innovation and sustainability. One of the most prominent trends is the rise of smart motors equipped with IoT capabilities. These motors can collect and transmit operational data in real-time, allowing for enhanced monitoring and predictive maintenance. This shift not only improves efficiency and reduces downtime but also supports data-driven decision-making in manufacturing environments.

Another significant trend is the increased focus on energy efficiency and eco-friendly designs. As industries strive to reduce their carbon footprint, manufacturers are developing motors that consume less energy without compromising performance. This emphasis on sustainability is complemented by the integration of advanced materials, such as lightweight composites and high-performance alloys, which optimize motor efficiency and longevity.

Furthermore, the advent of modular motor designs allows for easier upgrades and customization, ensuring that businesses can adapt to changing demands and technological advancements swiftly.

When selecting industrial motors in 2023, the debate between cost-effectiveness and quality is more prominent than ever. While budget constraints often lead companies to seek the lowest-priced options, sacrificing quality can result in increased maintenance costs and reduced efficiency. Finding the right balance is crucial for long-term success.

One effective tip is to assess your specific operational needs before making a purchase. Determine the required power, efficiency, and durability of the motor based on your applications. This targeted approach ensures that you invest in a motor that not only fits your budget but also meets performance standards.

Additionally, consider sourcing motors from reputable manufacturers that offer warranties and support. Investing slightly more upfront for a high-quality motor can lead to significant savings over time, as these products often come with better energy efficiency and lower failure rates. Always weigh the long-term operational costs against the initial purchase price to make an informed decision that aligns with your company’s goals.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.