Main Menu

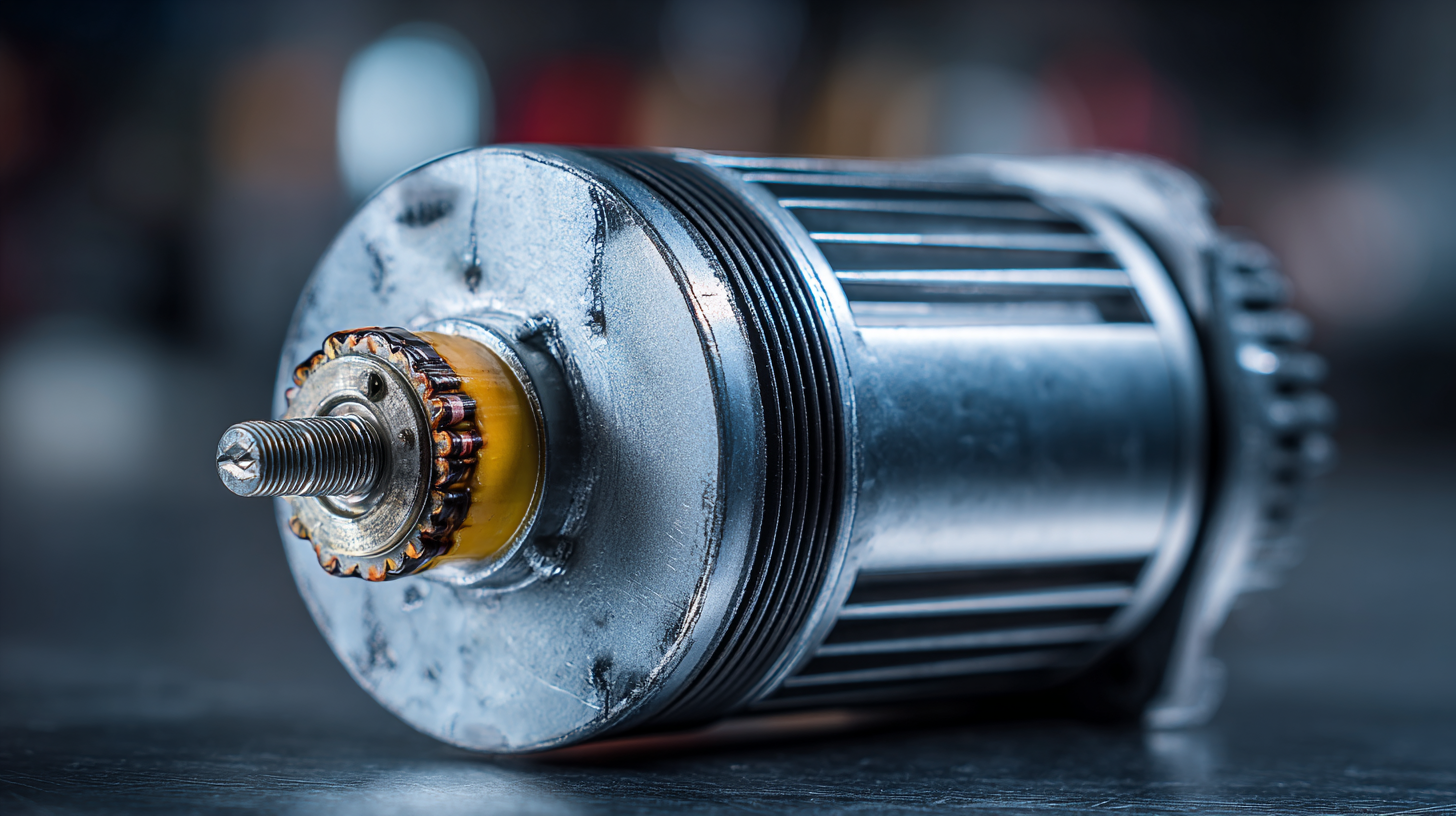

In the realm of modern engineering and manufacturing, the industrial DC motor stands out as a vital component due to its efficiency and reliability in powering various machinery. However, these motors are not without their challenges. As industries increasingly turn to automation and advanced technologies, understanding the common issues faced with industrial DC motors becomes essential for optimizing performance and minimizing downtime. From mechanical wear and thermal management to control system complexities, these issues can significantly impact productivity and operational costs. Moreover, exploring alternatives to traditional industrial DC motors may provide innovative solutions, enhancing their application in various sectors. This blog will delve into the prevalent challenges associated with industrial DC motors and shed light on potential alternatives that can meet the evolving demands of today's industrial landscape.

Selecting the right industrial DC motor for your application can present numerous challenges, particularly due to the wide variety of options available. One common issue is the lack of clarity in power ratings. According to a report by the International Electrotechnical Commission (IEC), nearly 30% of applications suffer from underperformance due to the selection of motors that do not meet the specific power requirements of the application. This mismatch can lead to inefficient operation and increased operational costs.

Another significant challenge in selecting industrial DC motors is the need for compatibility with control systems. Many manufacturers provide motors that seamlessly integrate with specific control equipment, but not all motors are created equal. A study by the National Electrical Manufacturers Association (NEMA) indicates that improper motor-controller pairing can result in performance inefficiencies of up to 25%. Thus, understanding the synergy between the motor type and the control technology is essential for optimal performance and reliability in industrial settings.

When it comes to industrial DC motors, understanding the impact of voltage and current ratings is crucial for optimizing performance and reliability. Voltage ratings indicate the maximum operating potential that a motor can handle. If a motor is subjected to voltage levels beyond its specifications, it can lead to overheating, insulation breakdown, or even catastrophic failure. Conversely, operating at lower voltage levels may result in insufficient torque and performance, causing delays in production processes.

Current ratings play an equally vital role, as they define the maximum current the motor can draw during operation. Exceeding this current limit can lead to excessive heat generation, which poses a risk for both the motor and the connected systems. A well-balanced current rating in conjunction with proper voltage ensures that the motor operates efficiently while minimizing energy consumption. Monitoring these parameters is essential for maintenance and can significantly enhance the lifespan of the motor, ensuring smoother operations in industrial applications.

| Motor Type | Voltage Rating (V) | Current Rating (A) | Power Output (W) | Efficiency (%) | Common Issues |

|---|---|---|---|---|---|

| Brushed DC Motor | 12 | 10 | 120 | 75 | Brush wear, overheating |

| Brushless DC Motor | 24 | 5 | 120 | 90 | Controller issues, start-up failure |

| Stepper Motor | 48 | 2 | 96 | 80 | Lost steps, heating issues |

| Permanent Magnet DC Motor | 36 | 8 | 288 | 85 | Magnet demagnetization, speed control |

Industries utilizing DC motors often encounter a variety of operational issues that can impede productivity and efficiency. One common problem is overheating, which is frequently caused by excessive load or inadequate ventilation. When DC motors run at high temperatures, their performance diminishes, potentially leading to permanent damage. To address this issue, it is crucial for operators to regularly monitor temperature levels and ensure that the motors are adequately cooled. Implementing preventive maintenance schedules can also help identify overheating trends before they escalate.

Another prevalent issue is commutation failure, which primarily occurs due to worn brushes or poor contact with the commutator. This malfunction can lead to erratic motor performance, including decreased torque and increased noise levels. To resolve this, industries should invest in high-quality brushes and perform regular inspections to replace worn components promptly. Additionally, educating staff on proper handling and maintenance techniques can reduce the incidence of commutation failures, ensuring smoother operations in the long run. By proactively addressing these issues, industries can maximize the lifespan and efficiency of their DC motors.

Efficiency standards play a crucial role in enhancing the reliability and performance of DC motors within various industrial applications. According to a report by the International Energy Agency (IEA), motors consume about 45% of global electricity use in industrial sectors. By implementing stringent efficiency standards, manufacturers can reduce energy consumption and increase the lifespan of DC motors. For instance, the adoption of high-efficiency DC motors can lead to energy savings of up to 20%, translating to significant operational cost reductions for businesses.

Efficiency standards play a crucial role in enhancing the reliability and performance of DC motors within various industrial applications. According to a report by the International Energy Agency (IEA), motors consume about 45% of global electricity use in industrial sectors. By implementing stringent efficiency standards, manufacturers can reduce energy consumption and increase the lifespan of DC motors. For instance, the adoption of high-efficiency DC motors can lead to energy savings of up to 20%, translating to significant operational cost reductions for businesses.

Moreover, compliance with efficiency standards not only helps in achieving better energy performance but also mitigates common issues faced with industrial motors, such as overheating and unplanned downtimes. The U.S. Department of Energy found that lower efficiency ratings can result in excessive heat generation, leading to premature failure of motor components. Therefore, by adhering to established efficiency benchmarks like NEMA Premium or IEC standards, industries can ensure that their DC motors operate reliably while contributing to sustainability goals. This holistic approach to motor efficiency not only enhances operational reliability but also supports the broader aim of reducing energy consumption in industrial environments.

When it comes to industrial applications, DC motors are pivotal for ensuring efficiency and reliability. However, prolonging the lifespan of these motors requires proactive maintenance practices. Regularly checking and addressing common issues such as brush wear, overheating, and electrical imbalances can significantly enhance their performance and durability.

One key maintenance practice is to routinely inspect the brushes and commutators. Tips for this include scheduling inspections every few months and replacing worn brushes promptly to avoid damage to the commutator. Additionally, ensuring proper lubrication of moving parts can reduce friction, which is crucial in preventing overheating and mechanical failures.

Temperature control is another critical factor in extending the lifespan of DC motors. It's essential to monitor the operating environment and implement measures to mitigate excessive heat exposure. Tips such as providing adequate ventilation and using cooling systems can help maintain optimal operating temperatures. Regular cleaning to remove dust and debris also contributes to better heat dissipation, ensuring the motor operates efficiently for years to come.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.