Main Menu

As industries increasingly embrace digital transformation, the demand for automation motors has surged, making them a crucial component in enhancing operational efficiency. According to a report by Research and Markets, the global automation motor market is expected to reach approximately $22 billion by 2027, growing at a compound annual growth rate (CAGR) of over 6%. This remarkable growth can be attributed to the rising adoption of automation technologies across various sectors, including manufacturing, oil and gas, and robotics. Choosing the right automation motors is vital for optimizing performance, energy efficiency, and cost-effectiveness in industrial applications. This guide aims to simplify the selection process by highlighting essential factors such as motor types, applications, and energy consumption, enabling businesses to make informed decisions that align with their operational goals.

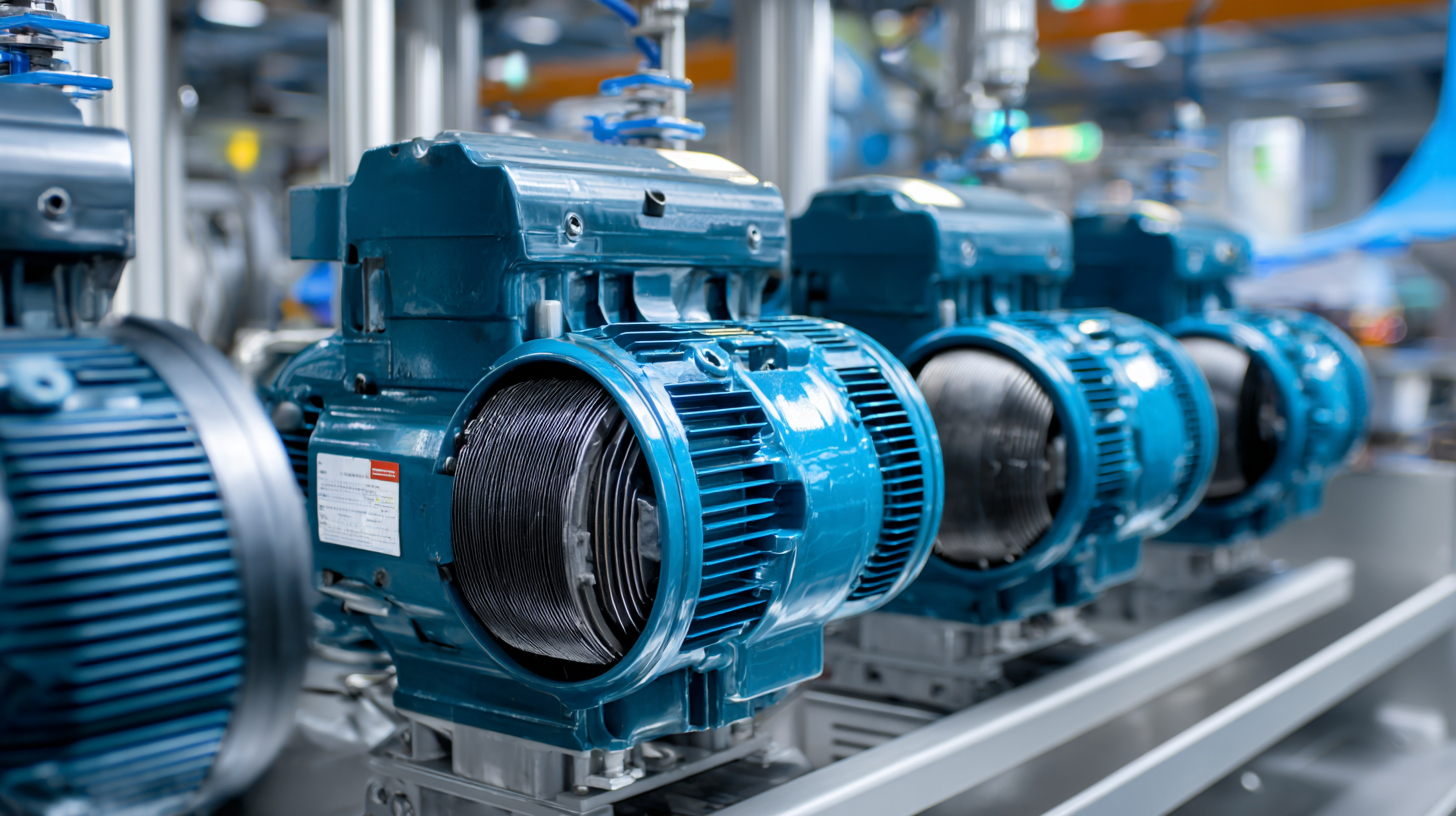

When selecting automation motors for industrial applications, it’s essential to understand the various types available, each designed with distinct features suited for specific tasks. The most common types include AC motors, DC motors, stepper motors, and servo motors. AC motors, widely used for their robustness and cost-effectiveness, are ideal for continuous operation in applications such as conveyor systems and pumps. According to a recent market report by Transparency Market Research, the global AC motor market is projected to reach $85.3 billion by 2026, reflecting their dominance in industrial settings.

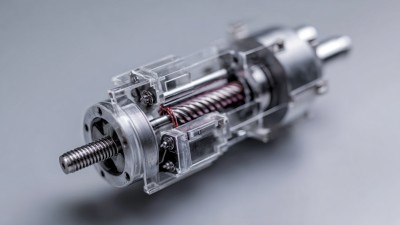

DC motors are favored for applications requiring variable speed control and high precision, such as robotics and automated machinery. They offer flexibility in speed adjustment and response time, making them suitable for applications that demand fine control. Furthermore, stepper motors are increasingly popular in automation due to their ability to move in discrete steps, allowing for precise positioning without the need for feedback systems. As highlighted in a report by Research and Markets, the stepper motor market is expected to grow significantly, driven by advancements in 3D printing and CNC machinery.

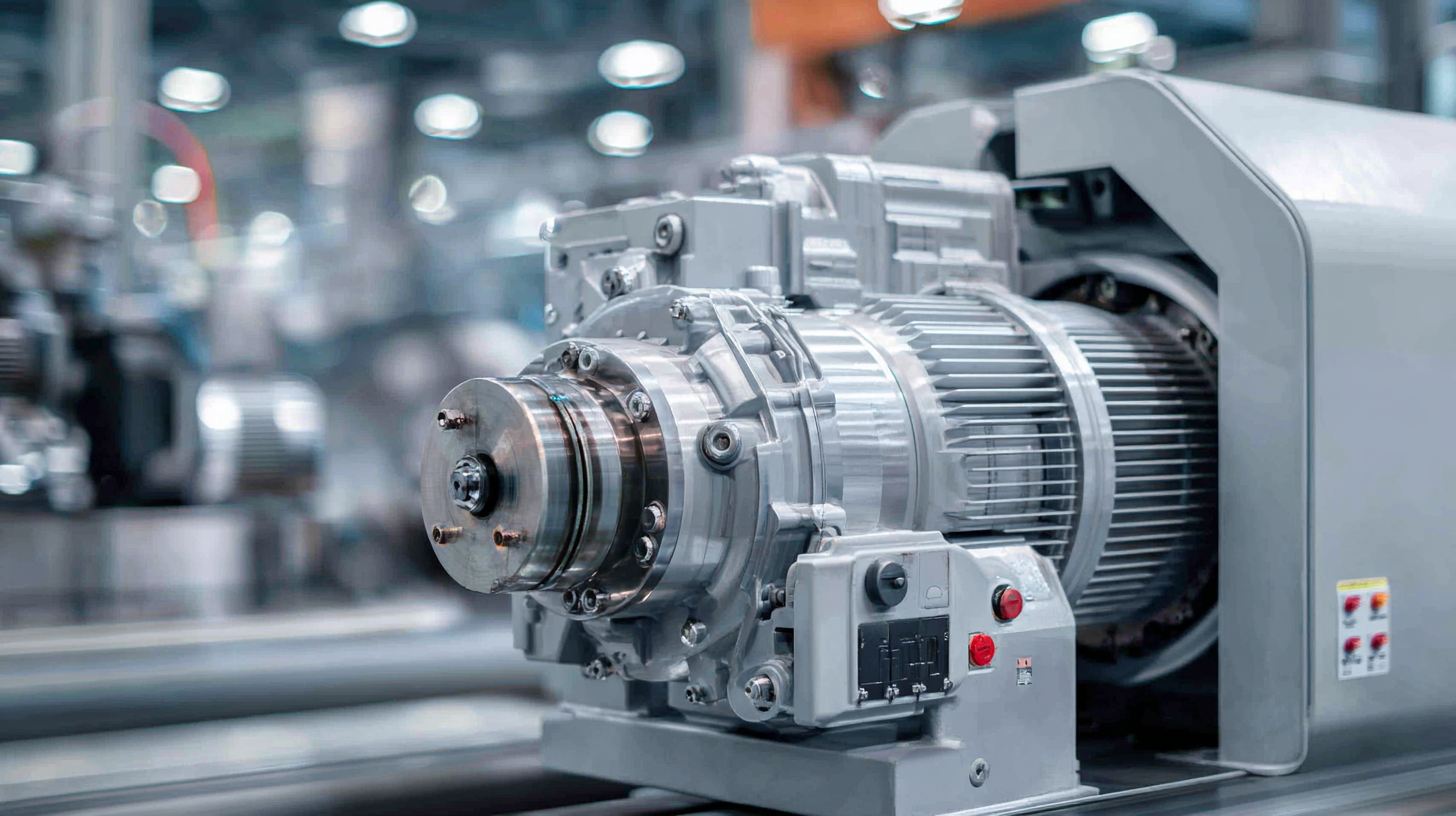

Lastly, servo motors excel in applications where high performance and accuracy are crucial. Their closed-loop control systems allow for precise motion control, making them ideal for tasks such as CNC machining and automated assembly lines. The demand for servo motors is projected to surge, as noted in a report by Mordor Intelligence, which estimates a compound annual growth rate (CAGR) of 6.5% in the automation motor market over the next few years. Understanding these motor types is vital for optimizing industrial operations and enhancing productivity.

When selecting automation motors for industrial applications, understanding the power and torque requirements is crucial. According to a report by the International Electrotechnical Commission, approximately 85% of industrial motors operate at less than 50% of their full capacity, indicating a prevalent issue of motor oversizing. This inefficiency can lead to increased operational costs and higher energy consumption. For specific applications, such as conveyor systems or robotic arms, it is essential to accurately assess the torque needed to overcome resistance and ensure optimal performance.

To make informed decisions, consider the following tips: First, calculate the required torque based on load characteristics and application dynamics. Industry standards suggest using the formula Torque = Force × Distance to ascertain the torque needed for your specific load conditions. Second, evaluate the power requirements using the formula Power = Torque × Angular Velocity, expressed in Watts, which will guide you in selecting a motor that is neither underpowered nor oversized for your application’s needs.

It's also important to account for environmental factors that may influence performance, such as temperature and humidity levels. A report from the Department of Energy highlights that motors operating in harsh environments may require additional protective features to maintain efficiency and longevity. By meticulously assessing these elements, you can ensure that the chosen motor will meet the demands of your industrial operations effectively.

When selecting the appropriate automation motors for industrial applications, environmental factors and operating conditions play a crucial role in ensuring optimal performance and longevity. Variables such as temperature, humidity, and exposure to dust or corrosive substances should be thoroughly evaluated. For instance, in high-temperature environments, motors with enhanced cooling systems or those designed to withstand extreme heat can prevent overheating and degradation of materials.

Furthermore, understanding the operational conditions, such as load demands and duty cycles, is essential. Motors that will experience frequent starts and stops may need a different specification compared to those that operate continuously under heavy loads. Selecting the appropriate motor type—whether it’s an AC, DC, or servo motor—should align with these conditions to maximize efficiency. Additionally, considering the placement of the motor and potential spatial constraints can influence the choice of size and type, ensuring that it meets both performance expectations and environmental requirements effectively.

When selecting automation motors for industrial applications, the significance of control options cannot be overstated. Control features directly influence a motor's performance, efficiency, and adaptability to various operational environments. Understanding the types of control methods available—such as variable frequency drives (VFDs), servo systems, or direct on-line (DOL) starters—can help determine which motor will best meet specific requirements. For example, VFDs allow for precise speed control, which is critical in processes where variable speeds enhance productivity and reduce energy consumption.

When selecting automation motors for industrial applications, the significance of control options cannot be overstated. Control features directly influence a motor's performance, efficiency, and adaptability to various operational environments. Understanding the types of control methods available—such as variable frequency drives (VFDs), servo systems, or direct on-line (DOL) starters—can help determine which motor will best meet specific requirements. For example, VFDs allow for precise speed control, which is critical in processes where variable speeds enhance productivity and reduce energy consumption.

Additionally, the integration of advanced control technologies, such as programmable logic controllers (PLCs) and intelligent motor controllers, can further optimize motor performance. These systems enable real-time monitoring and adjustments, ensuring that the motor operates within its ideal parameters, thus prolonging its lifespan and minimizing downtime. By carefully assessing the importance of these control options during the selection process, businesses can enhance operational efficiency and achieve better results in their industrial activities.

When selecting automation motors for industrial applications, assessing cost efficiency is paramount. The initial purchase price of a motor is just one aspect; it’s vital to consider its operational costs over time. Energy-efficient motors, despite a higher upfront investment, often result in significant savings on electricity bills. Moreover, they typically offer enhanced performance, leading to lower overall operational costs. Evaluating the total cost of ownership rather than just the purchase price can help businesses make smarter financial decisions.

Long-term maintenance needs are another critical factor in the selection of automation motors. Choosing motors that are designed for durability and ease of maintenance can reduce downtime and repair costs. Regular maintenance schedules and the availability of replacement parts play a crucial role in minimizing disruptions to operations. Investing in motors from reputable manufacturers that offer robust warranties and support can also enhance reliability. By prioritizing these aspects, companies can ensure a seamless and cost-effective integration of automation motors into their operations.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.