Main Menu

Choosing the right 240v motor can seem overwhelming. With many options available, it’s easy to get lost in technical details. A 240v motor powers a range of applications. From industrial machinery to home appliances, understanding your needs is key.

Consider the power requirements of your project. A motor’s capacity must align with your specific use. Think about size, speed, and torque. These factors help determine the best motor type. There’s no one-size-fits-all solution. You might need to explore various models.

While some motors promise efficiency, they may fall short in real-world applications. Researching online reviews and customer feedback can provide insights. However, don't just trust all reviews blindly. Seek advice from experts in the field. A 240v motor should meet both your current and future requirements. Balancing performance and cost is essential.

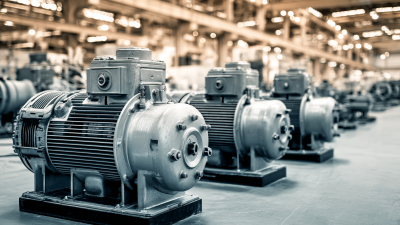

When selecting a 240V motor, understanding its basics is crucial. These motors are widely used in industrial applications. They provide good torque and efficiency. According to industry data, over 70% of electric motors operate below 240V. This makes them popular for various tasks, including pumping, HVAC systems, and conveyor belts.

Choosing the right motor involves several factors. Consider the load type and environmental conditions. A motor used in a dusty environment should have a higher IP rating. Current specifications are also vital. A motor running at 20 amps will need appropriate wiring to prevent overheating.

Tips: Always check the efficiency rating of the motor. Higher efficiency can lower operating costs. Don't overlook the importance of a proper enclosure to protect the motor. Regular maintenance enhances performance and longevity. Remember, a poorly chosen motor can lead to operational failures and increased costs. Take time to assess your needs thoroughly before making a decision.

When selecting a 240V motor, clearly identifying your power requirements is crucial. Power requirements largely depend on the application and load. For example, a HVAC system may require a motor with higher torque. Many industry reports suggest that motors for industrial applications typically range from 0.75 kW to 15 kW. This variability reflects the diversity in machinery and operational demands.

Understanding your specific needs is essential. You should assess the load type—whether it's continuous or intermittent. Continuous loads need more precise calculations. A comprehensive study indicates that nearly 30% of businesses miscalculate power needs, leading to inefficiency. Overloading a motor can shorten its lifespan by up to 50%. On the other hand, underutilizing a motor wastes energy.

Consider the efficiency rating. High-efficiency motors consume less energy. According to the U.S. Department of Energy, switching to an efficient motor can reduce energy consumption by 2-8%. However, higher efficiency often comes at a premium cost. You may need to weigh upfront expenses against long-term savings. Reflect on these complexities to choose wisely.

When choosing between AC and DC motors, specific needs matter greatly. AC motors are often preferred for industrial applications. These motors can handle high loads, making them suitable for heavy machinery. According to the National Electrical Manufacturers Association (NEMA), around 60% of industrial motors are AC types. They tend to be more efficient for operational costs in these settings.

On the other hand, DC motors bring different advantages. They offer precise speed control and high torque at low speeds. This makes them ideal for applications requiring fine adjustments. A 2021 report from the International Electrotechnical Commission (IEC) highlighted that many robotics and automotive industries rely on DC motors for this reason. However, they can be costly to maintain and not always suitable for high power applications. It's essential to weigh these factors carefully.

Considering your requirements can be challenging. Think about energy efficiency, torque needs, and budget constraints. The right choice depends on the specific application. Don't ignore potential hidden costs, such as maintenance and replacement. Re-evaluating your motor needs can save money in the long run.

| Motor Type | Voltage | Power Rating (HP) | Efficiency (%) | Applications |

|---|---|---|---|---|

| AC Motor | 240V | 1.5 HP | 85% | Pumps, Fans, Compressors |

| DC Motor | 240V | 2 HP | 90% | Electric Vehicles, Robotics |

| Brushless DC Motor | 240V | 1 HP | 92% | HVAC systems, Home Appliances |

| Synchronous Motor | 240V | 3 HP | 88% | Industrial Applications, Conveyor Systems |

| Induction Motor | 240V | 2 HP | 87% | Machinery, HVAC, Fans |

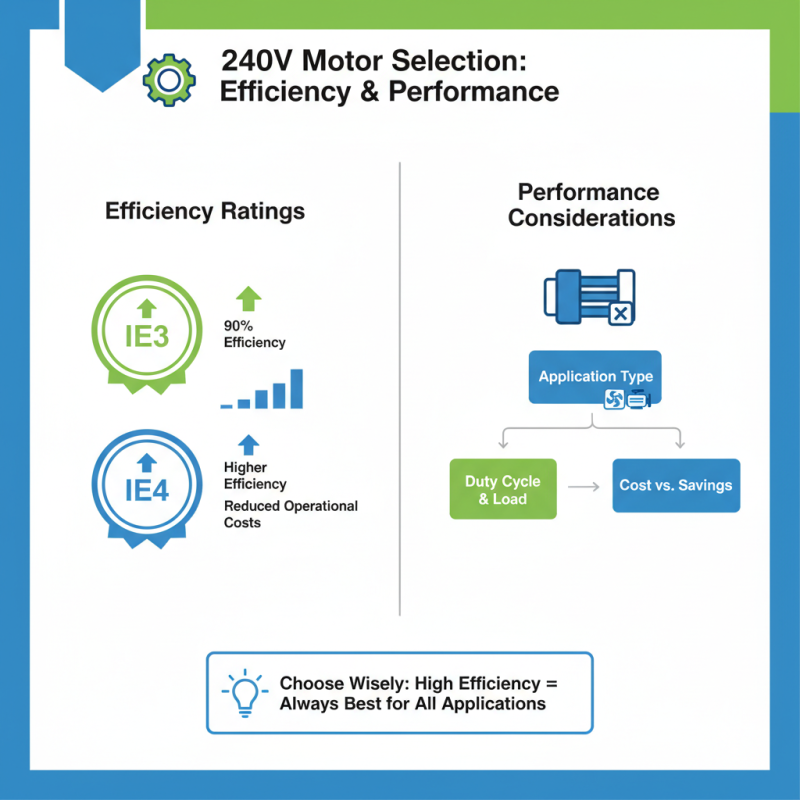

When selecting a 240V motor, understanding efficiency and performance ratings is crucial. Efficiency ratings often come in terms like IE3 or IE4, indicating the motor's energy-saving capabilities. According to recent industry reports, IE3 motors can achieve efficiencies exceeding 90%. This reduces energy consumption and operational costs. Yet, not all applications will benefit from the highest efficiency rating.

Performance ratings reveal how motors respond under load. A motor’s torque curve is vital for applications needing consistent power. Some motors may perform well initially but decline in output under heavy loads. This can lead to premature wear. Data suggests that motors with a better torque-to-weight ratio can provide increased reliability and efficiency in such scenarios.

Choosing the right motor isn’t just about numbers. It's about understanding your specific needs. While high efficiency is attractive, ensure it aligns with your application requirements. Sometimes a lower-rated motor may perform better due to design or application suitability. Balancing efficiency and performance is often a nuanced decision that requires careful thought.

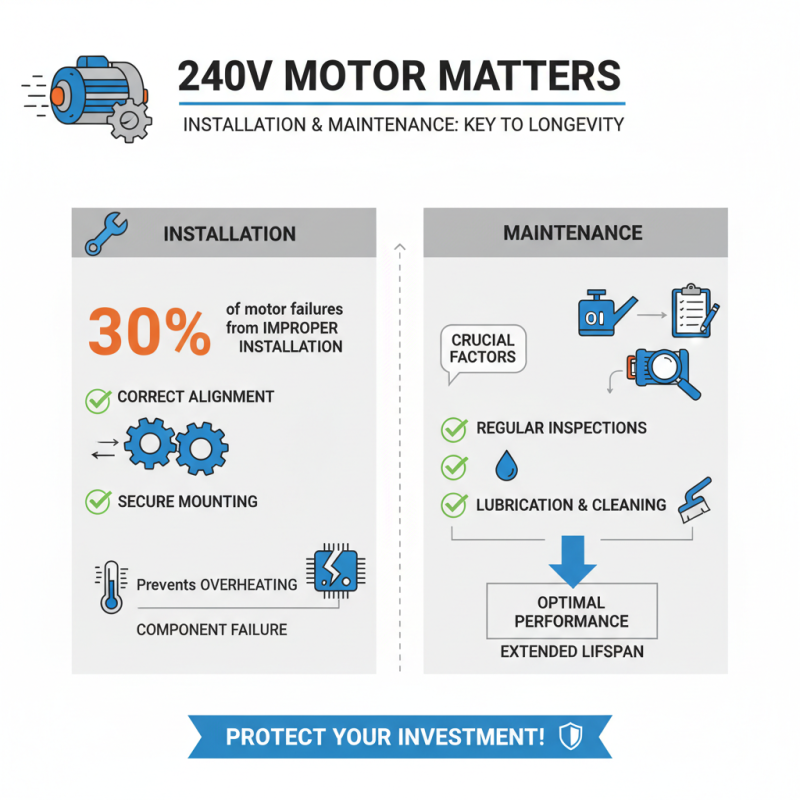

When choosing a 240V motor, installation and maintenance are crucial factors. These considerations can greatly affect performance and lifespan. Incorrect installation can lead to overheating or component failure. According to industry data, nearly 30% of motor failures stem from improper installation methods. Ensuring that the motor is aligned correctly and securely mounted is essential.

Moreover, regular maintenance is integral for optimal functioning. Many professionals recommend scheduled inspections every three to six months. This practice can help identify wear and tear. Monitoring motor temperatures can prevent serious damage. Data shows that motors running at or above recommended temperatures reduce lifespan significantly. Simple maintenance tasks, like cleaning and lubrication, are often overlooked. However, they can greatly extend the life of a motor.

Environmental conditions should also be assessed. Dust, humidity, and heat can impact motor efficiency. In fact, one study found that harsh environments can shorten motor lifespan by up to 50%. Therefore, using protective enclosures can be beneficial. However, protective measures must be balanced with ventilation needs. Finding that balance is often an ongoing challenge for users.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.