Main Menu

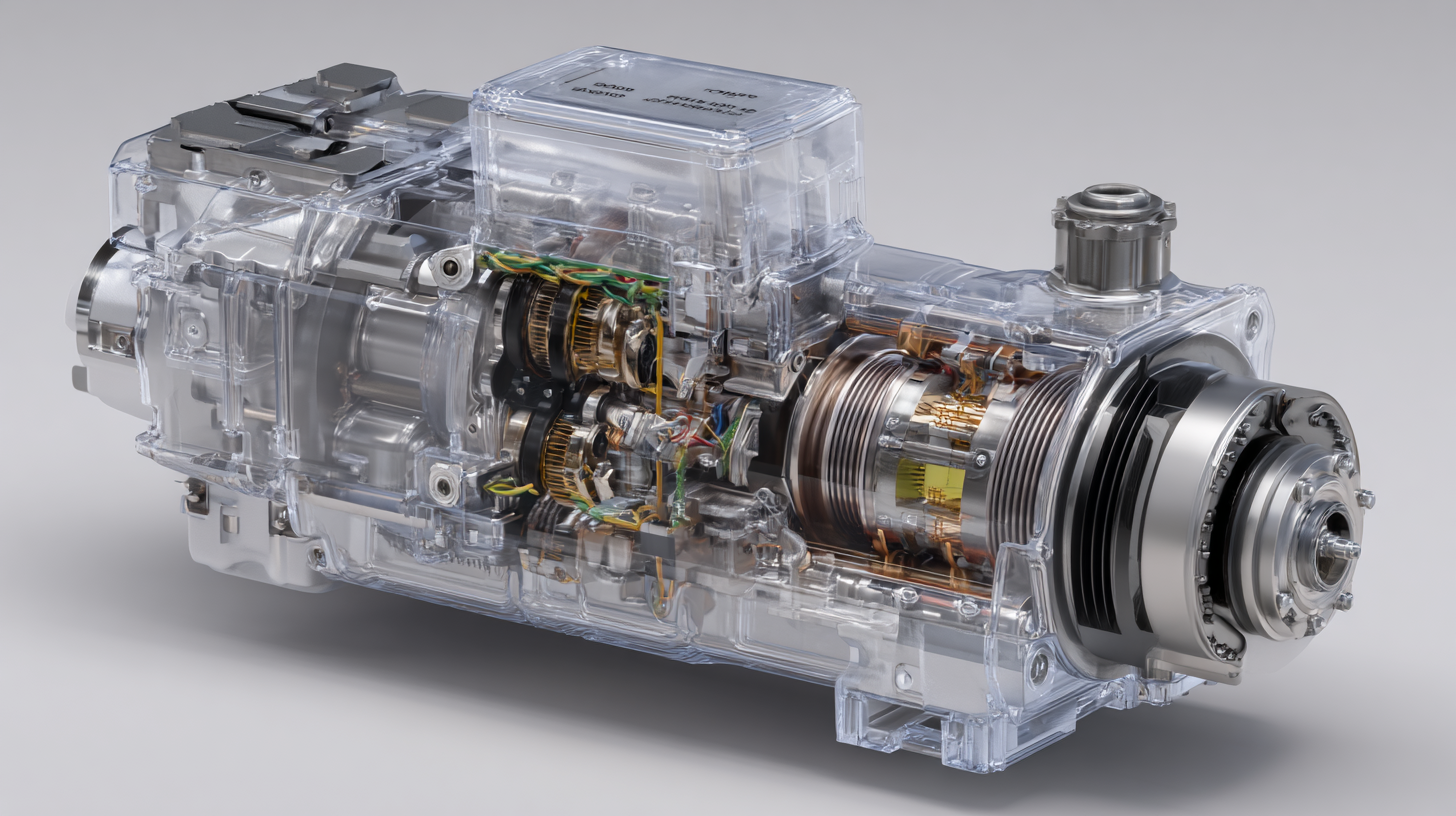

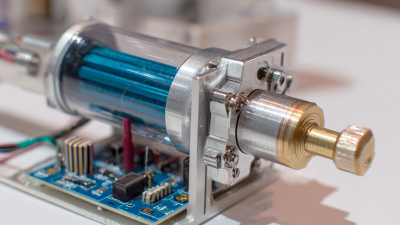

In the realm of robotics, selecting appropriate dc motors for robots is a pivotal factor that significantly influences overall performance and efficiency. These electric motors serve as the driving force behind a robot's movement, dictating its speed, torque, and responsiveness to commands. The intricacies involved in the choice of dc motors encompass various aspects such as power requirements, load capacities, and control mechanisms. By understanding the nuances of different motor types and their specifications, engineers and designers can optimize the functionality of robotic systems for specific applications, whether it’s for industrial automation, consumer gadgets, or complex autonomous vehicles.

In the realm of robotics, selecting appropriate dc motors for robots is a pivotal factor that significantly influences overall performance and efficiency. These electric motors serve as the driving force behind a robot's movement, dictating its speed, torque, and responsiveness to commands. The intricacies involved in the choice of dc motors encompass various aspects such as power requirements, load capacities, and control mechanisms. By understanding the nuances of different motor types and their specifications, engineers and designers can optimize the functionality of robotic systems for specific applications, whether it’s for industrial automation, consumer gadgets, or complex autonomous vehicles.

This exploration of dc motors for robots not only underlines the critical nature of proper selection but also emphasizes the impact of these components on the success and reliability of robotic endeavors.

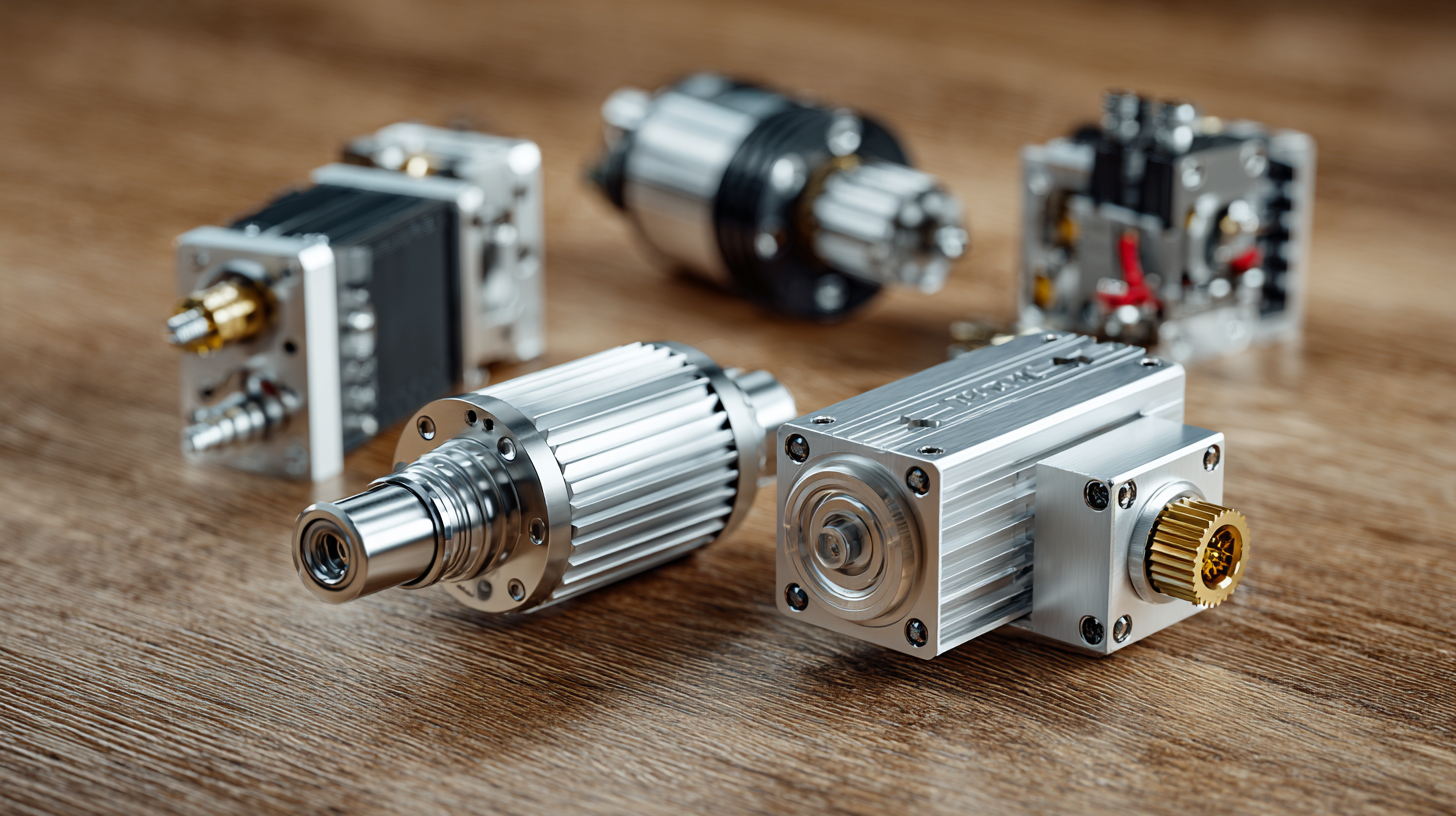

When it comes to robotics, the choice of DC motors can significantly impact the overall performance and functionality of a robot. Understanding the different types of DC motors available is crucial for engineers and enthusiasts alike. Common options include brushed DC motors, brushless DC motors, and stepper motors. Brushed motors are affordable and easy to control, making them ideal for simple applications. In contrast, brushless motors offer higher efficiency and longevity, making them well-suited for more complex robotic systems.

**Tips:** When selecting a DC motor, consider the torque and speed requirements of your application. A motor with insufficient torque will struggle to perform tasks, while one that is too powerful can lead to excessive wear and energy waste. Additionally, assess the available space in your robot; compact designs may benefit from smaller motors, which help save space without compromising on performance.

Another key factor is the voltage rating, as it affects the motor's power and speed. Ensure that the motor you choose can operate within the voltage limits of your robotic system. Understanding the trade-offs between different motor types will help you make informed decisions that enhance your robot's capabilities and reliability.

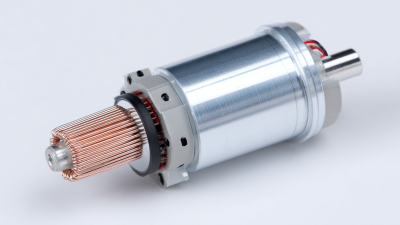

When selecting DC motors for your robots, several key factors play a crucial role in their performance. One of the primary considerations is the torque requirement. It’s essential to assess how much load your robot will carry and choose a motor that can adequately provide the necessary torque. Motors with higher torque ratings might be needed for applications involving heavy lifting or fast movements.

Additionally, speed and efficiency are vital parameters. The operating speed of the motor greatly affects the robot’s overall capability. Make sure to consider the motor's RPM (Revolutions Per Minute) and match it to your robot's requirements. Efficiency is also important; selecting a motor that offers optimal performance without excessive power consumption will enhance your robot's battery life and functionality.

**Tips:** Always review the specifications of different motor models, and where possible, test them in a controlled environment. It’s also advisable to consult with professionals or seek recommendations from industry peers. Finally, ensure that the motor dimensions are compatible with your robot’s design to avoid any mechanical issues.

| Factor | Description | Impact on Performance |

|---|---|---|

| Voltage Rating | The operating voltage of the motor, affecting speed and torque. | Critical for achieving desired speeds; mismatch can lead to performance issues. |

| Current Rating | The maximum continuous current the motor can handle. | Determines the power capability and overheating risk. |

| Torque | The rotational force produced by the motor. | Crucial for moving heavy loads and overcoming inertia. |

| Speed (RPM) | The rotational speed of the motor, measured in revolutions per minute. | Affects the overall agility and responsiveness of the robot. |

| Gear Ratio | The ratio of motor speed to wheel speed. | Impacts torque and speed; must match robot design goals. |

| Size and Weight | Physical dimensions and weight of the motor. | Affects robot design, center of gravity, and mobility. |

| Durability | The ability of the motor to withstand wear, shock, and environmental factors. | Important for longevity and reliability in operation. |

When selecting DC motors for robotics, understanding torque and speed requirements is crucial for achieving optimal performance. Torque is the rotational force that a motor generates, and it's essential for overcoming resistance and moving the robot's components. Speed, measured in RPM (revolutions per minute), determines how fast the robot can operate and complete tasks. Balancing these two factors ensures that the robot can perform its intended functions efficiently, whether it’s navigating obstacles or lifting heavy objects.

When selecting DC motors for robotics, understanding torque and speed requirements is crucial for achieving optimal performance. Torque is the rotational force that a motor generates, and it's essential for overcoming resistance and moving the robot's components. Speed, measured in RPM (revolutions per minute), determines how fast the robot can operate and complete tasks. Balancing these two factors ensures that the robot can perform its intended functions efficiently, whether it’s navigating obstacles or lifting heavy objects.

Tips: Always calculate the load the robot will encounter. This will give you a clear idea of the torque needed. Additionally, consider the application's speed requirements; a higher RPM motor may be necessary for tasks requiring quick movements, while slower, high-torque motors are ideal for heavy lifting.

Selecting the right DC motor based on these torque and speed considerations can significantly enhance your robot's performance. It's important to consult the motor's specifications and match them with your project's specific needs. Testing different motor configurations can also provide insights into how well your robot performs under various conditions and loads.

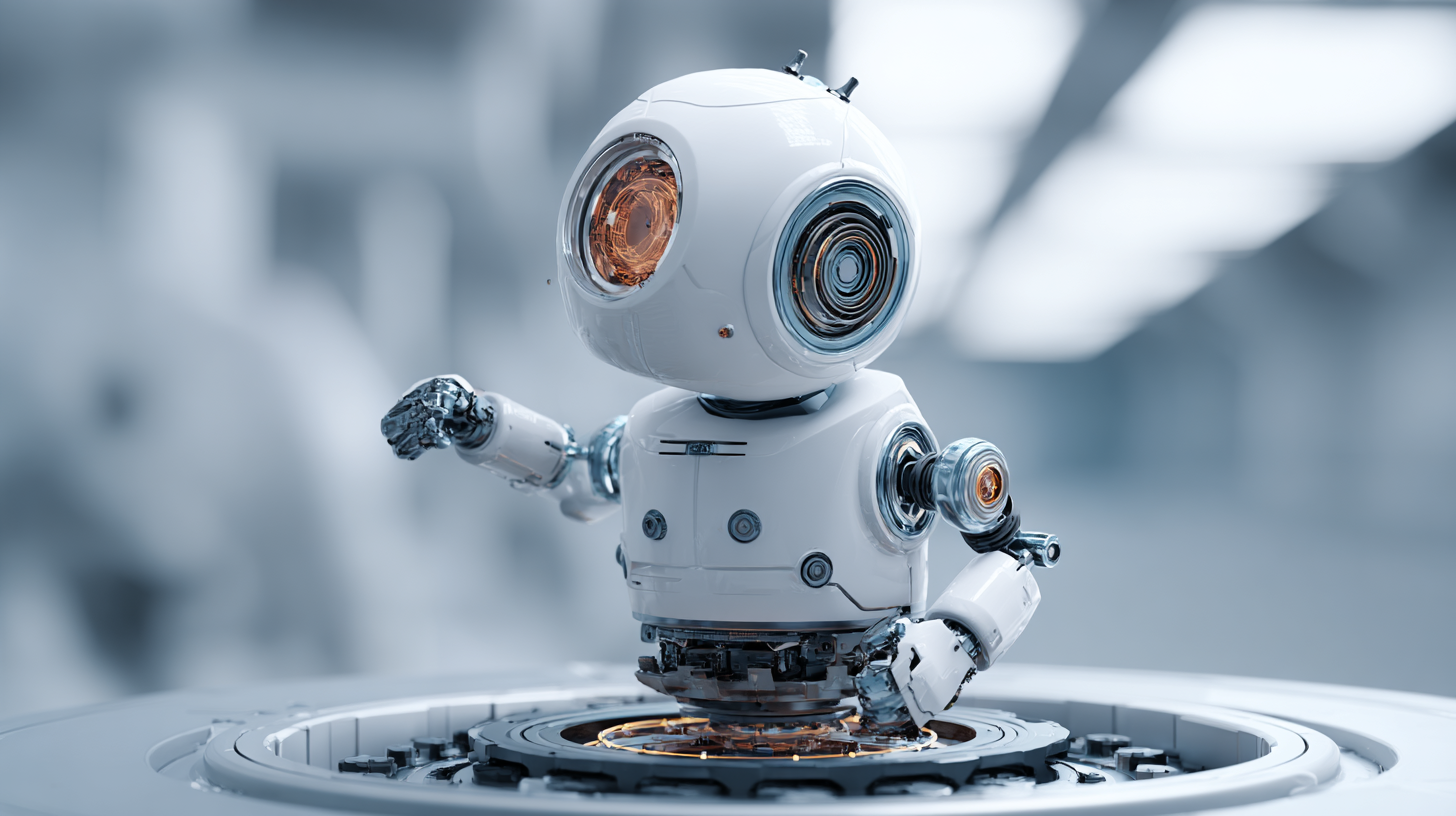

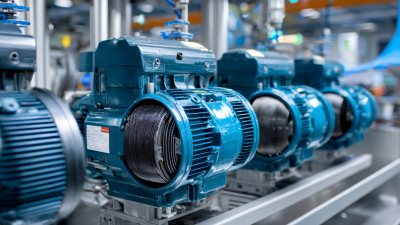

Selecting the appropriate DC motors is crucial for optimizing a robot's performance based on its design and intended functionality. Each robot has unique requirements influenced by its size, weight, and operational environment. For instance, a lightweight robotic arm may prioritize precision and speed, necessitating motors with high RPM and low torque. Conversely, a mobile robot may require motors that deliver higher torque to navigate uneven terrain effectively. Understanding these dynamics aids designers in matching motor specifications with the robot's intended tasks.

Moreover, compatibility between motor specifications and robotic functions extends to factors such as power consumption, lifespan, and control interface. For example, an application demanding long operational hours may benefit from energy-efficient motors that reduce wear and prolong functionality. Additionally, if the robot operates in complex environments, motors with easy-to-integrate control interfaces can streamline the design process. By carefully aligning motor characteristics with the robot's design and desired outcomes, engineers can ensure not only effective performance but also enhance the overall reliability and longevity of the robotic system.

When selecting DC motors for robotics, avoiding common mistakes can significantly enhance performance and reliability. One critical error is neglecting to match the motor specifications to the robot’s application needs. For instance, choosing a motor that cannot handle the required torque can lead to inefficient operations or even mechanical failure. It’s crucial to consider the load conditions, speed requirements, and duty cycles the robot will encounter during performance.

Another common pitfall is overlooking the importance of motor control. Many designers fail to implement suitable control systems that maximize the motor's capabilities, such as using closed-loop control to ensure precise movements. Additionally, not accounting for voltage variations or power supply stability can result in reduced performance or erratic behavior. By avoiding these pitfalls and ensuring that DC motors are properly selected and integrated, engineers can significantly boost the functionality and longevity of robotic systems.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.