Main Menu

Choosing the right motors for your project is a critical step that can significantly influence overall efficiency and performance. According to industry expert Dr. Emily Hart, a leading figure in the motors motor sector, "Selecting the appropriate motor is not just about matching specifications; it’s about understanding the unique requirements of your application and how various motors can meet those needs." With an extensive array of options available, decision-makers often find themselves overwhelmed, which can lead to inefficiencies and increased costs.

In this guide, we will delve into the essential factors to consider when selecting motors for your project. From understanding torque requirements to evaluating energy efficiency, having the right knowledge can greatly enhance your project’s success. The motors motor industry is advancing rapidly with innovations that offer improved performance and sustainability. By leveraging expert insights and practical tips, you can ensure that your choice not only fulfills technical criteria but also contributes to the overall success and sustainability of your initiative.

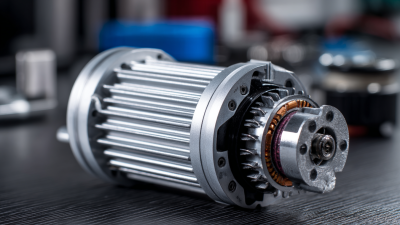

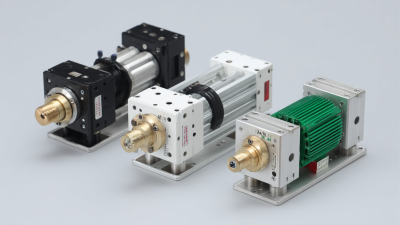

When selecting motors for your project, it's essential to understand the different types available and their respective applications. Motors can be broadly classified into several categories, including induction motors, brushless DC motors, and stepper motors. Each of these motor types has unique characteristics that suit specific tasks. For instance, induction motors are widely used in industrial applications due to their robustness and ability to handle high torque. Conversely, brushless DC motors offer high efficiency and precise control, making them ideal for electric vehicles and robotics.

The applications of motors are vast, and with the rise of electric vehicles, the demand for advanced motor solutions has increased significantly. Engineers are now exploring innovative designs that minimize reliance on rare earth elements while maintaining high performance. Additionally, as industries seek automation, the importance of motors in driving efficiency and productivity cannot be overstated. Understanding the operational principles of various motor types, as well as their advantages and limitations, is crucial in maximizing the efficiency of your projects and making informed decisions in motor selection.

When selecting the right motor for your project, several key factors must be considered to ensure optimal performance and efficiency. First, it's essential to assess the specific requirements of your application, including load capacity, required torque, and speed range. Understanding these parameters will guide you in choosing a motor type that meets your needs—whether it's an AC motor, DC motor, or a stepper motor.

Tip: Always evaluate the environmental conditions where the motor will operate. Factors such as temperature, humidity, and exposure to dust or corrosive elements can impact the motor's performance and longevity. Make sure the chosen motor can withstand these conditions.

Another crucial consideration is the motor’s energy efficiency, which not only affects operating costs but also contributes to the sustainability of your project. High-efficiency motors can significantly reduce energy consumption, leading to lower costs and a smaller ecological footprint over time.

Tip: Look for motors that comply with energy efficiency standards. Additionally, consider implementing feedback systems that can optimize motor performance based on real-time data, enhancing operational efficiency. These practices will help you maximize the value and performance of your motor selection for successful project outcomes.

When selecting motors for your project, understanding energy efficiency ratings is crucial for maximizing performance and minimizing operational costs. Energy-efficient motors can significantly reduce electricity consumption, which is essential as industries and residential sectors increasingly focus on sustainability. For instance, advanced motor technologies utilize integrated controls and optimized designs to enhance efficiency, paving the way for smarter and more energy-effective systems.

Recent innovations reveal the importance of adopting systems that prioritize energy efficiency. New tools, such as the Pumping System Assessment Tool, help industrial users analyze the efficiency of their pumping operations. With standards like MENS being introduced globally, the push for higher energy efficiency in motor systems aligns with environmental goals. By investing in high-efficiency motors and leveraging the latest technologies, organizations can achieve substantial energy savings while ensuring robust performance in their applications.

When selecting motors for your project, comparing cost and maintenance is crucial in determining the best value. According to a report by the International Electrotechnical Commission (IEC), lifecycle costs can surpass initial purchasing costs by up to 2.5 times, emphasizing the importance of taking maintenance into account. High-efficiency motors, while potentially more expensive upfront, can significantly reduce operational costs over time, providing savings in energy bills that can justify the initial investment.

Tips: Always consider the Total Cost of Ownership (TCO) model when evaluating motor options. This approach includes not just the initial purchase price but also the estimated maintenance costs and energy consumption over the motor’s lifespan. According to the U.S. Department of Energy (DOE), upgrading to premium efficiency motors can yield energy savings of 3-8% compared to standard motors, translating into significant savings in electricity costs and reducing the frequency of maintenance required.

Additionally, maintenance strategies such as predictive maintenance can enhance motor longevity and reliability. Implementing a condition-monitoring system could lead to a potential reduction in maintenance costs by up to 30%, as noted by the Maintenance Center of Excellence. This method allows for timely interventions that help avoid more extensive repairs down the line, ensuring your project operates at peak efficiency.

As we approach 2025, significant advancements in motor technology are anticipated, particularly with the ever-growing demands of electric mobility and robotics. The global electric bicycle motor market is projected to surge from $12.79 billion in 2025 to $33.41 billion by 2032, reflecting a remarkable compound annual growth rate (CAGR) of 14.7%. This robust growth highlights the increasing consumer interest and investment in sustainable transportation solutions.

In addition, the humanoid robot market is expected to evolve significantly between 2025 and 2035, with emerging technologies and applications in automotive and logistics sectors. With a forecasted CAGR over this period, businesses must strategize to harness these opportunities effectively.

**Tips:** When choosing motors for your projects, consider the intended application—whether that's for electric vehicles, robotics, or consumer electronics—to ensure optimal efficiency. Stay informed about industry trends and forecasts, as these insights can help steer your design decisions towards more sustainable and cost-effective solutions in the rapidly changing market landscape.

| Motor Type | Efficiency (%) | Torque (Nm) | Speed (RPM) | Power Rating (kW) | Future Trend |

|---|---|---|---|---|---|

| DC Motor | 85 | 1.5 | 3000 | 2 | Increased integration with IoT |

| AC Induction Motor | 90 | 2.0 | 1800 | 3 | Higher efficiency standards |

| Brushless DC Motor | 95 | 1.0 | 4000 | 1.5 | Rise of sustainable materials |

| Step Motor | 80 | 0.5 | 200 | 0.5 | Smart control and automation |

| Servo Motor | 92 | 3.5 | 5000 | 4 | Integration with advanced robotics |

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.