Main Menu

In the rapidly evolving landscape of modern technology, the precision DC motor stands out as a quintessential component in a myriad of applications, from robotics to consumer electronics. Understanding the basics of precision DC motor technology is essential for engineers, hobbyists, and tech enthusiasts alike, as it plays a critical role in enabling precise control and efficient performance in various operations. This blog aims to demystify the key aspects of precision DC motors, exploring their operational principles, advantages, and applications, while also addressing the various types available in the market today. By delving into the intricacies of this technology, we will provide insights that empower readers to make informed decisions when integrating precision DC motors into their projects or products, ultimately leading to enhanced functionality and innovation in their respective fields.

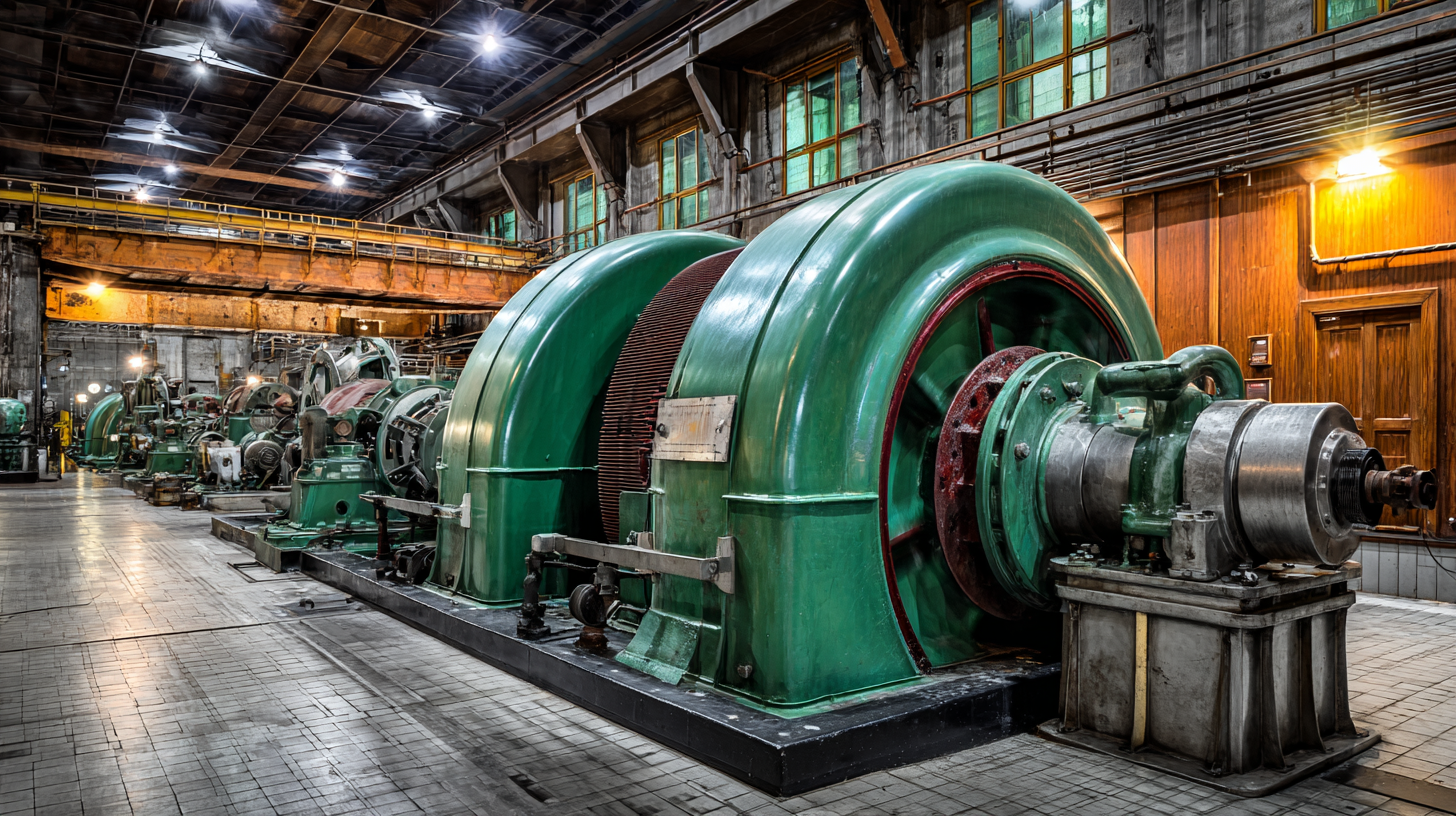

Precision DC motor technology has become an essential focus in various industries, ranging from robotics to aerospace, due to its unmatched accuracy and reliability. At the core of this technology is the ability to control the speed and position of the motor with high precision. Precision DC motors are engineered to minimize errors in torque and positioning, making them ideal for applications that require meticulous control. This level of precision is achieved through advanced feedback systems and high-quality components, ensuring that even the most delicate tasks can be performed with confidence.

The versatility of precision DC motors is another significant advantage. They can be easily integrated into complex systems, providing smooth operation across a wide range of conditions. This adaptability, combined with their robust performance, makes them invaluable in automated manufacturing processes, medical equipment, and various consumer electronics. By understanding the fundamentals of precision DC motor technology, engineers and designers can harness its capabilities to enhance product performance and elevate operational efficiency, ultimately driving innovation across multiple sectors.

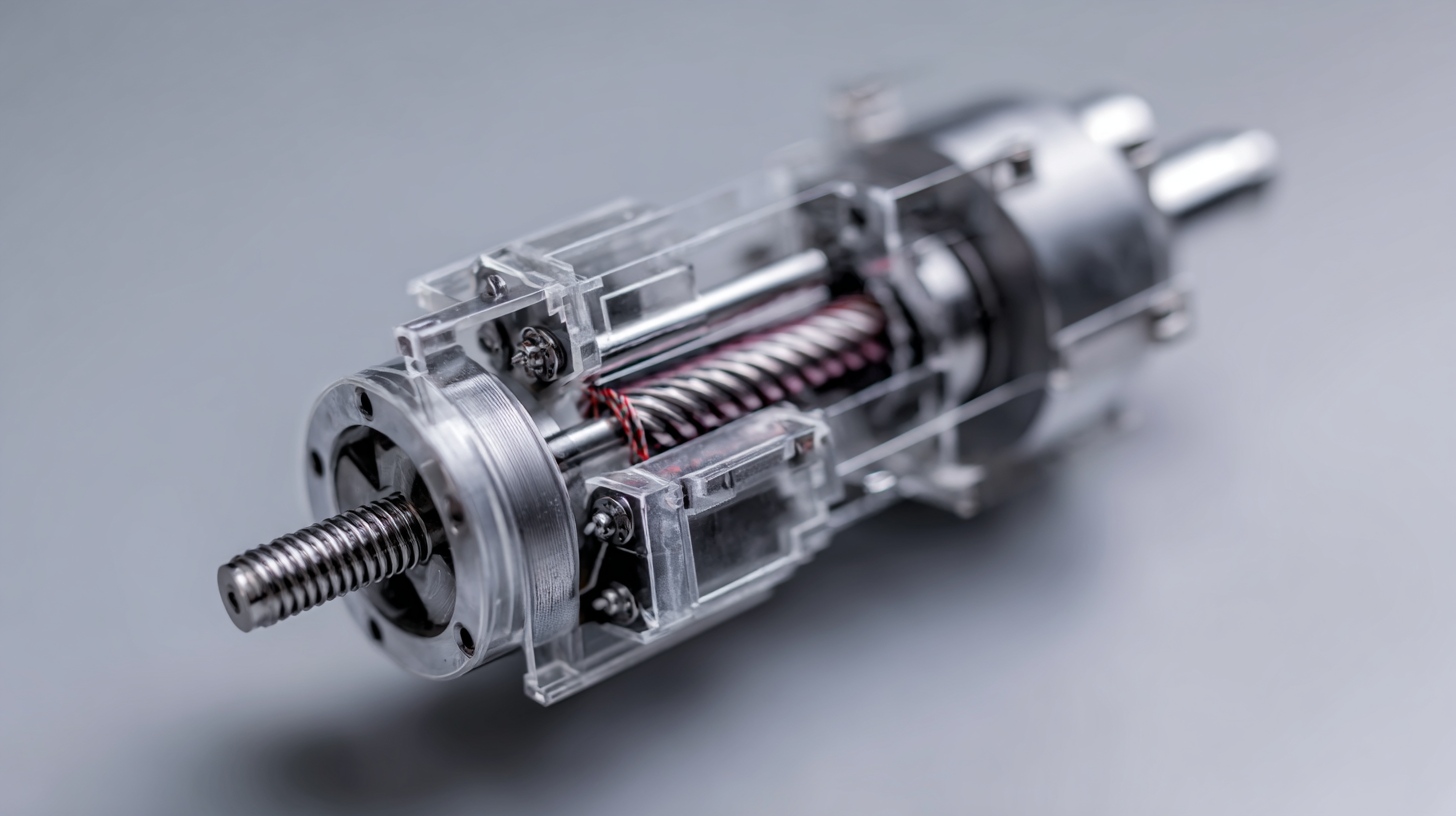

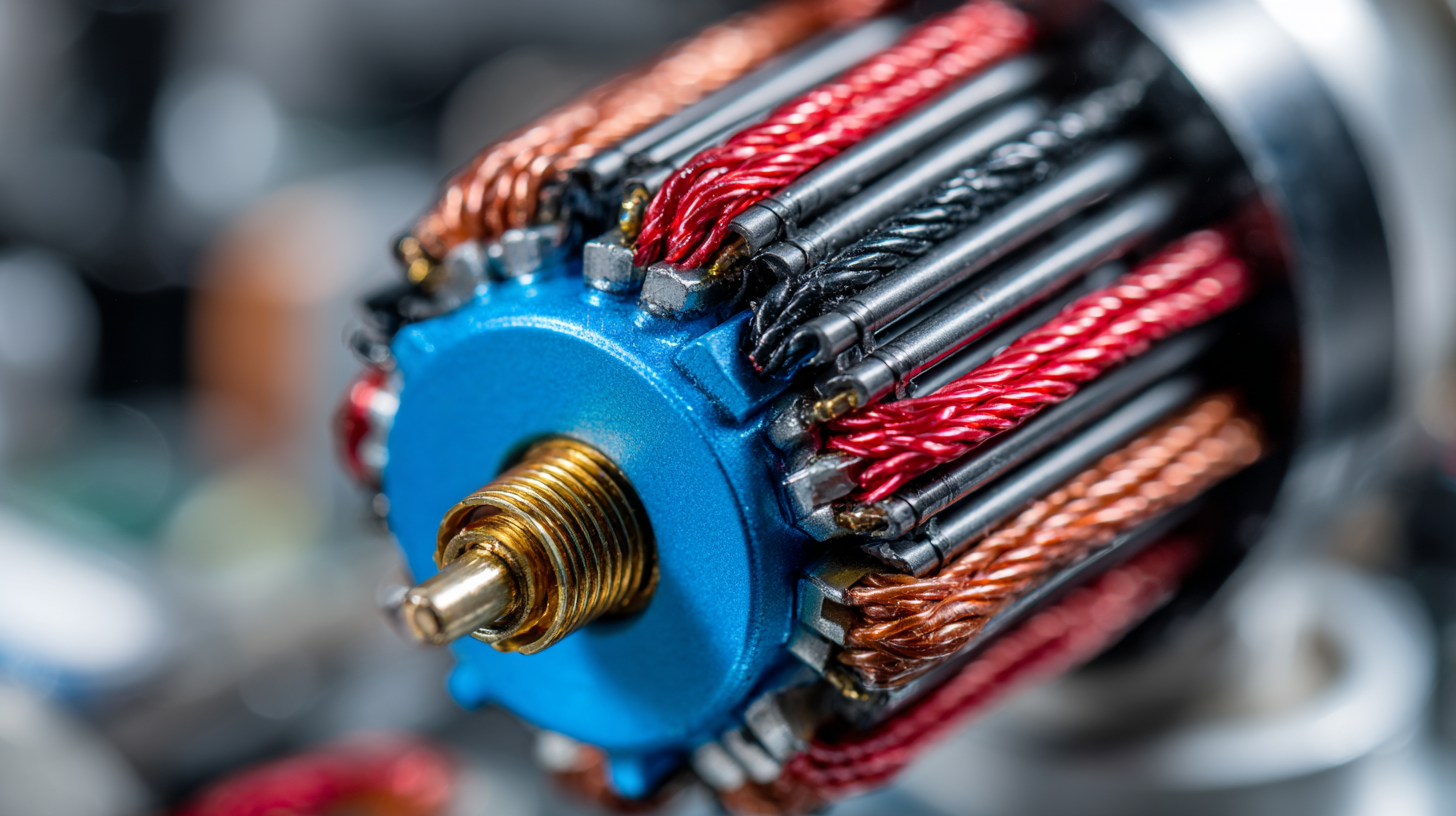

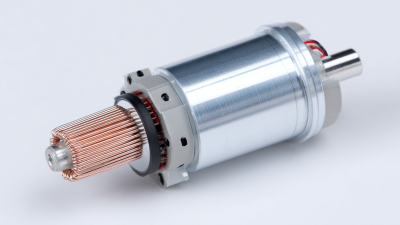

Precision DC motors are vital components in various applications, from robotics to automotive systems. Their efficiency is largely influenced by several key components, including the armature, commutator, and the rotor. The armature serves as the component where the electrical energy is converted to mechanical energy, while the commutator ensures the current direction is switched correctly, allowing for continuous rotation. The rotor, which is the rotating part of the motor, works in conjunction with permanent magnets or electromagnetic fields to create motion.

Reports have shown that the market for precision DC motors is experiencing substantial growth, projected to reach approximately $3.4 billion by 2025, with a CAGR of around 6.5% from 2020 to 2025. The rising demand for electric vehicles and automation solutions is driving this growth. Notably, companies specializing in precision motor technology are increasingly investing in research and development to enhance motor efficiency and lifespan, thereby meeting the industry’s stringent requirements. This shift towards advanced motor solutions underscores the importance of understanding and optimizing the key components that make precision DC motors exceptionally reliable and effective.

Precision DC motors are fundamental components in modern automation and motion control systems, where their ability to deliver accurate positioning and smooth motion is crucial. At the core of how these motors operate is the principle of electromagnetism, which allows for efficient conversion of electrical energy into mechanical motion. The fundamental design of brush-type DC motors has remained largely unchanged, yet innovations in control systems, such as Adaptive Neuro-Fuzzy Inference System (ANFIS) controllers, have significantly enhanced their operational precision.

When implementing precision DC motors, it's vital to optimize both the motor's design and the control algorithms used. Recent advancements have shown that hybrid motor designs can increase torque density by over 200%, indicating a trend towards greater efficiency and performance.

**Tips:**

1. Always consider the specific application requirements when choosing a DC motor to ensure optimal performance.

2. Regular testing and validation of motor control algorithms can lead to improved precision and response times in automation systems.

3. Keeping abreast of advancements in motor technology will help in making informed decisions for system upgrades and improvements.

| Parameter | Description | Typical Values |

|---|---|---|

| Voltage Rating | The operating voltage of the motor | 6V - 24V |

| Current Draw | The amount of current consumed during operation | 100mA - 5A |

| Speed Range | The range of rotational speeds achievable | 1000 - 5000 RPM |

| Torque | The rotational force produced by the motor | 0.5 - 2 Nm |

| Size | Physical dimensions of the motor | 20mm - 100mm diameter |

| Efficiency | Ratio of output power to input power | 70% - 90% |

| Control Method | Technique used to control the motor's operation | PWM, Analog Voltage |

Precision DC motors have become essential components in various modern technologies due to their high efficiency and accuracy. One of the most notable applications is in robotics, where these motors enable precise movements and control, making them ideal for tasks ranging from assembly lines to surgical instruments. Their ability to deliver consistent torque at various speeds allows robots to perform intricate tasks with minimal error, thus enhancing productivity and safety.

Another significant application of precision DC motors can be found in the field of aerospace and automotive technology. In aerospace, these motors are utilized in actuators for flight control systems, ensuring reliable operation under extreme conditions. In automotive applications, they are used in electric power steering systems and seat adjustments, providing users with both comfort and improved vehicle handling. The integration of precision DC motors in these areas demonstrates their critical role in advancing technology and improving user experience.

Precision DC motors are increasingly favored in various applications due to their exceptional control over speed and torque. According to a recent report from Research and Markets, the global precision motor market is expected to grow at a CAGR of 6.3% from 2022 to 2027, highlighting the growing demand for optimized performance in sectors like robotics, aerospace, and medical devices. One significant advantage of precision DC motors is their ability to deliver high efficiency at low power levels, which is essential for energy-sensitive applications. They typically exhibit efficiency levels exceeding 90%, as noted in a study by the IEEE.

Another critical aspect is their inherent simplicity and ease of integration into electronic systems. Unlike their AC motor counterparts, precision DC motors do not require a complex start-up mechanism, eliminating the need for additional components, which can reduce overall system costs. The flexibility in design also allows for a compact footprint, which is particularly advantageous in applications where space is at a premium. Additionally, their linear torque-speed relationship ensures that precise adjustments can be made without introducing significant delays or overshoot, a feature that is vital in automation and control systems, as confirmed by findings from the International Journal of Advanced Manufacturing Technology.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.