Main Menu

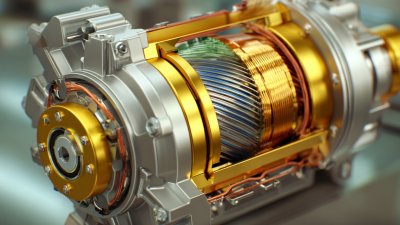

In the evolving landscape of manufacturing and industrial applications, the significance of industrial motors cannot be overstated. As key drivers of efficiency and productivity, these motors play a crucial role in facilitating operations across various sectors. With the industry's growing focus on data-driven solutions, understanding the best-performing industrial motors for 2025 becomes essential for businesses looking to enhance their operational capabilities.

This article delves into the top ten industrial motors projected to lead the market in 2025 by evaluating their performance metrics, reliability, and adaptability to modern technological advancements. By emphasizing proven data-driven strategies, we aim to provide insights that empower businesses to make informed decisions, thereby optimizing their processes and achieving sustainable growth. As we explore each of these motors, we will highlight their unique features and advantages, making it easier for industry professionals to select the right solutions for their specific needs.

As we approach 2025, the industrial motor technology landscape is witnessing transformative changes driven by advancements in efficiency, connectivity, and sustainability. One of the emerging trends is the integration of IoT-enabled motors which facilitate real-time monitoring and predictive maintenance. According to a report by McKinsey, the global market for smart industrial motors is expected to reach $10.3 billion by 2025, growing at a CAGR of 6.5%. This shift not only reduces downtime but also promotes energy efficiency, aligning with sustainability goals across industries.

Another notable trend is the focus on electric motors, particularly in light of increasing legislative pressure for carbon neutrality. The International Energy Agency (IEA) indicates that electric motors account for approximately 45% of global electricity consumption in industrial applications. The shift towards high-efficiency motors driven by advanced materials and design techniques can lead to energy savings of up to 10-15%, significantly decreasing operational costs. Additionally, variable frequency drives (VFDs) are becoming standard as they optimize energy consumption according to actual load requirements. This confluence of technology is setting the stage for enhanced operational efficiencies in industrial settings by 2025.

Evaluating the efficiency of industrial motors involves a keen understanding of key performance metrics that drive operational success. In 2025, organizations should focus on parameters such as energy consumption, output power, and reliability. By scrutinizing these efficiency metrics, businesses can identify opportunities for optimization, reducing operational costs while enhancing productivity. The integration of advanced analytics and AI tools can further streamline this evaluation process, enabling better decision-making based on real-time data insights.

As industries advance towards greater automation and digitalization, the role of energy efficiency becomes increasingly critical. The concept of energy efficiency as the "first fuel" emphasizes its potential to significantly reduce carbon footprints in manufacturing processes. Companies must now prioritize not only the procurement of efficient motor technologies but also the adoption of comprehensive measurement strategies that leverage AI for analyzing everything from energy use patterns to predictive maintenance needs. By doing so, they can ensure their motor systems are performing at peak efficiency, ultimately leading to a more sustainable and competitive industrial landscape.

In recent years, the significance of data-driven approaches in the optimization of industrial motor performance has grown exponentially. By leveraging advanced analytics and machine learning algorithms, industries can gain profound insights into motor operation, leading to enhanced efficiency and performance. These innovative strategies help identify patterns and anomalies in motor usage, enabling proactive maintenance and minimizing downtime. By implementing predictive analytics, companies can forecast potential failures and optimize maintenance schedules, thereby extending motor lifespan and improving overall productivity.

Moreover, the integration of Internet of Things (IoT) technology has revolutionized how motors are monitored and controlled in real time. Sensors installed on motors continuously collect data on various parameters such as temperature, vibration, and load. This wealth of information allows for real-time adjustments and fine-tuning, ensuring that motors operate at peak efficiency. As industries adopt these data-driven solutions, the result is not only a reduction in operational costs but also a significant decrease in energy consumption, aligning with the global push for sustainability and eco-friendly practices in industrial operations.

| Motor Type | Efficiency Rating (%) | Power Output (kW) | Torque (Nm) | Operating Temp (°C) | Lifespan (hours) | Data-Driven Optimization Approach |

|---|---|---|---|---|---|---|

| Induction Motor | 94 | 75 | 210 | 40 | 50,000 | Predictive Maintenance Algorithms |

| Brushless DC Motor | 90 | 50 | 150 | 50 | 30,000 | Real-Time Performance Monitoring |

| Synchronous Motor | 95 | 100 | 300 | 60 | 70,000 | Optimization Algorithms |

| Stepper Motor | 85 | 10 | 30 | 45 | 20,000 | Data Analysis for Load Testing |

| Servo Motor | 92 | 20 | 75 | 50 | 40,000 | Closed-Loop Feedback Systems |

| Permanent Magnet Motor | 96 | 80 | 220 | 55 | 60,000 | Machine Learning for Efficiency Gains |

| Linear Motor | 89 | 90 | 250 | 30 | 25,000 | Data-Driven Modelling Techniques |

| Multi-Phase Motor | 93 | 65 | 200 | 50 | 55,000 | Simulation-based Performance Tests |

| Electronically Commutated Motor | 91 | 40 | 180 | 45 | 35,000 | Data-Driven Condition Monitoring |

| Switched Reluctance Motor | 88 | 55 | 170 | 50 | 40,000 | Efficiency Analysis Techniques |

The comparative analysis of the 2025 top 10 industrial motors reveals a significant shift towards efficiency-driven designs that leverage advanced data analytics. According to a recent report from the International Energy Agency, electric motors account for approximately 70% of industrial electricity consumption. Therefore, the right choice of motor can lead to substantial energy savings. Brands like Siemens and ABB have demonstrated up to 15% improvements in energy efficiency through innovative technology and optimized manufacturing processes.

When evaluating motors, consider the total cost of ownership, not just the initial purchase price. Advanced motors with smart technology can provide real-time data on performance, allowing for predictive maintenance that can reduce downtime by 30%, as highlighted in a study by McKinsey & Company. Such data-driven insights can empower companies to minimize operational costs while maximizing productivity.

Tip: Look for motors that offer integrated IoT capabilities, enabling seamless connectivity and data collection. This feature can be essential in achieving high operational efficiency and reliability in the long term. Industries that embrace these advancements will not only enhance their productivity but also play a crucial role in sustainable energy consumption.

The integration of advanced industrial motors across various sectors has led to significant enhancements in efficiency and productivity. According to a report by the International Energy Agency, industrial motors account for approximately 70% of the total energy consumed in manufacturing. In the automotive industry, for instance, the adoption of high-efficiency motors has been shown to reduce energy consumption by up to 30%, translating directly into lower operational costs and a reduced carbon footprint.

In the food and beverage sector, the deployment of smart motors equipped with IoT technologies has revolutionized production lines. A survey conducted by the Food Processing Industry Council revealed that companies using data-driven motor solutions reported a 25% increase in process efficiency. Real-time monitoring allows for predictive maintenance, minimizing downtime and ensuring that production schedules are consistently met. Furthermore, these motors contribute to an overall increase in product quality through enhanced precision in handling ingredients and packaging processes.

As industries continue to evolve, the reliance on innovative motor solutions not only optimizes performance but also supports sustainability goals. With advanced analytics driving these technologies, manufacturers can fine-tune their processes to achieve maximum efficiency while adhering to environmental standards.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.